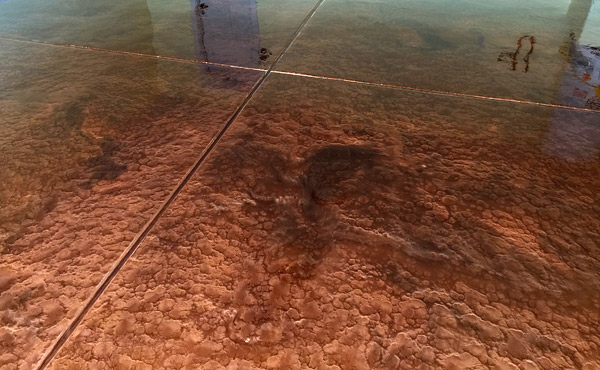

Colorful mica pigments designed to be dispersed in a variety of binders are part of what makes metallic epoxy floors so alluring. The right combination of binders and finish coats create a unique three-dimensional appearance on seamless floors that can offer an unmatched blend of beauty and durability. Depending on the application techniques used, the finished floors’ look can range from elegant to exotic.

You can install metallic epoxy floors anywhere a truly unique finished floor is the desired outcome. This can range from retail establishments, nightclubs and automobile showrooms to residential interiors, backyards and garage floors. When I talk to my customers, it’s critical that I understand what they want or what they need their metallic floor to accomplish. Most don’t really know what goes into a metallic floor. All they know is that they like the pictures they see.

Two sides to metallics

Metallic floors always involve a 100 percent solid epoxy or a very high-solid polyaspartic. There are two considerations that I like to explain to my customers: their cosmetics and their durability.

Cosmetically, metallic floors are beautiful with the color disbursements, three-dimensional looks and effects that transpire from install to dry. When the floor system is applied and the installer’s work completed, there will still be movement in the product caused by the natural flow of the concrete and the pull of gravity.

On the technical side, metallic floors are among the most durable, impact-resistant flooring systems. Their only drawback, in my opinion, is that their typical high-gloss finish makes them more prone to scratches. However, you can reduce that risk by applying a polyurethane topcoat with a satin finish. I also tell both my residential and commercial customers to maintain the floor with wax. This way any scratches will be in the wax and not in the actual floor. So when the floor is rewaxed, the scratches are gone.

As for being slippery, metallic floors are no slicker than solid pigmented floors, chip floors or bare concrete. If slipperiness is a major concern, I apply aluminum oxide in the 100 percent solid epoxy, not the polyurethane clear coat.

Choosing colors and solvents

One thing that makes metallic floors so different from other systems is that the epoxy or polyaspartic is clear, so when you add the colored metallic powder, that’s all you’ll see. Since metallic systems are so translucent, when using multiple colors you should always use the darkest color in your prime coat for proper hide.

When choosing colors, I break it down to three categories.

- Earthtones – browns, beiges and copper

- Exotics – purples, reds, yellows, oranges, greens and blues

- Contemporary – an assortment of grays

As an aside, white is the hardest color to do because metallic floors are very translucent.

I don’t recommend mixing colors together from these three categories. I do recommend keeping the mix to no more than three colors, with my preference being two, otherwise the floor tends to look really busy. When it comes to residential interiors, I recommend only one color with no solvent effects. Inside a home, the solvent effects can look too busy and eventually there might be too much movement going on.

Take care but don’t be afraid to experiment

Solvents can help give a metallic floor a swirling “movement” and also create craters that provide a three-dimensional look. Just remember not to apply your solvent or any effect right after you installed the metallic system. You should wait until the floor gets to the tacky stage, because that way your effects will not flood back. A guiding point is to touch the floor with your finger and, if it leaves a print, you’re good to go.

When installing metallic floors, don’t be afraid to experiment with new things. I cannot stress this enough. Different types of solvents produce different effects.

If the solvent evaporates slower than the epoxy cures, you’ll have “soft pockets” in your floor, areas where the solvent is trapped underneath the epoxy. To get the best results, follow the manufacturers’ mixing instructions and don’t over-apply solvent.

If you do not add a solvent, the floor will look like an acid stain with the colored powder flowing naturally throughout the floor depending on gravity and the levelness of the concrete.

When installing a metallic system, there are a lot of different techniques you can use to manipulate the surface. These techniques include rolling out your product or squeegeeing it. You can also use different props such as a leaf blower or an air compressor to move it around.

Imperfections make the floor

Because no two metallic floors will ever be alike, never make a sample board for a client. You’re only going to hurt yourself and disappoint your customers.

The biggest thing to understand about these incredible floors is they are only as good as the artistic ability of the installer. You don’t just open up a can and out they come. It takes practice and perseverance to hone your technique.

If customers want a perfect floor, this is not the system for them. They would be better off with a chip system, a stamped pattern or a polished concrete floor.

Trade secrets

As a licensed contractor I have had my share of getting beat up by both consumers and the Registrar of Contractors because of their lack of knowledge and misunderstanding about what constitutes a metallic floor. Each floor will vary in looks inch by inch. Even if you don’t use a solvent for certain effects, the floor will still have a natural flowing look. This is due to the highs and lows in the surface and the pull of gravity. Think of how a waterfall works.

For commercial jobs, I always ask my customers if they would like to include a vinyl decal of their logo, company name or something that matches their design concept in their floor for a nice finishing touch. But be careful. While decals can look nice they can also take away from the beauty of the floor if they are not designed right. Decals always go on before your clear polyurethane topcoat.

For commercial jobs, I always ask my customers if they would like to include a vinyl decal of their logo, company name or something that matches their design concept in their floor for a nice finishing touch. But be careful. While decals can look nice they can also take away from the beauty of the floor if they are not designed right. Decals always go on before your clear polyurethane topcoat.

In closing, there are many things you can do to a metallic floor and many ways to do them. My advice is to experiment and discover that secret recipe that works for you and keep it under wraps. Like an accomplished chef, you may share your general recipe but never reveal that one ingredient that makes your mix a stand-out among others.

Questions from Readers

Question

What solvents do you recommend for epoxy/resin art?

Answer from Concrete Decor

I believe that the effects you are looking at in the article are achieved using denatured alcohol. If you spritz the alcohol onto the surface after applying the metallic coating but during the curing process, you will achieve the look you are going for.