Builders and remodelers interested in learning more about how homes and businesses can be fortified with concrete to withstand Florida’s extreme weather conditions and climate should plan to attend the Concrete Decor Show Expo Wednesday and Thursday, Nov. 8-9, at the Innisbrook Resort and Golf Club in Palm Harbor, Florida.

Attendees can learn about everything from insulated concrete forms, wall coverings and specialty mixes to countertops, flooring and polishing concrete from the more than 50 exhibitors displaying their goods and services.

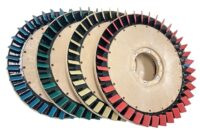

Several outdoor demonstrations are scheduled throughout the show including applications of decorative treatments to ICFs and power trowel polishing that will showcase Lavina attachments, slurry management systems, coverings and guard applications.

“Concrete is a proven superior material that can stand up to most anything,” said Bent Mikkelsen, Concrete Decor Show promoter and the publisher of Concrete Decor magazine. “Besides being used structurally with excellent results, it also can project high aesthetic value. When used as an architectural finish, builders have less materials to inventory and haul to the job site.”

ICFs save on labor and time

Insulated concrete forms, such as the ones at the show that will be exhibited by Fox Blocks, an Omaha, Nebraska, company with 22 manufacturing plants nationwide. Often hailed as “big boy Legos,” ICFs are double-insulated reinforced concrete blocks that can be used below grade as well as above grade for everything from homes to commercial buildings. And just like Legos, they come in an assortment of shapes including straight, curved and corners to accommodate architectural design features.

“Our ICFs are a five-in-one system: concrete form, plastic rebar holders, insulation for wall, furring strip for attaching drywall, and an air and vapor barrier,” said Mike Kennaw, vice president of marketing and sales for Fox Blocks. Instead of having five trades coming in to do work, you’ve accomplished all those steps in one fell swoop. “The labor savings are significant.”

John Riddle, vice president of business development for Turning Leaf Construction in Sanford, Florida, said his company is a Fox Blocks distributor as well as a custom home builder that has been using ICFs for nearly 10 years. “In Florida, you need something that will stand up to large wind volumes. But even more importantly in this market you need to have properly insulated walls because of our constant warm, moist environment.” ICFs fill that bill with insulation on the interior and exterior walls and concrete in between.

Compared to concrete masonry units (CMUs), ICFs assemble quicker and are so much easier to handle. “One Fox Blocks (unit) forms nearly 5½ square feet of wall area and weighs 3 pounds,” Riddle said, compared to a CMU that forms less than 1 square foot of wall area and weighs 35 pounds.

During the show, Fox Blocks will demonstrate how ICFs are stacked and rebar is placed. Experienced concrete contractors and framers, Kennaw said, typically find the building process very user friendly.

“It saddens me as a human that people keep rebuilding the same way repeatedly although the technology is out there to build structures that will withstand these high wind and heavy rain events,” said Riddle, who plans on attending the expo to discover other ways concrete products can benefit his company. “It may cost a little bit more to build with ICFs but what is the value of your life?”

Ultra high-performance mix designs

If you think concrete is an ordinary building material with limited uses, think again. “It’s a better way to build,” said Mikkelsen, “for both inside and outside projects. There are so many exciting things that are constantly being improved upon when it comes to mix designs.”

Take for instance the products manufactured by Kingdom Products out of Throop, Pennsylvania. The company will debut its new fast, self-leveling polishable overlay and will floor the inside of a car with a cementitious product that will be made to look like textured wood.

But the product that’s sure to catch contractors’ attention is an ultra high-performance mix design that cures to between 15,000 and 20,000 psi and beyond.

“It can be cast into anything,” said Bart Sacco, founder and owner of Kingdom Products and Concrete Texturing LLC. “It can be used to cast shutters for window coverings. Or it can be used to make siding.” Siding and shutters made from this product would be hard to destroy with a sledge hammer and virtually impenetrable to flying debris, he adds.

He said the mix comes in one-component and two-component variations. “We’ve got a mix where you just add water or it can be formulated to accept other liquid additives,” he said. “A precast operation we supply casts a 23,000 psi self-compacting mix. This is a crazy strong mix — with the proper fiber additions a mix design of this nature can be virtually indestructible.”

See concrete in action at expo

The expo part of the show will be held from noon until 6 p.m. Wednesday and Thursday, Nov. 8 and 9. Tickets to the two-day event are $25 in advance and $35 at the door.

If you’re interested in learning about a particular area of decorative concrete, there is a gamut of hands-on workshops, educational seminars and panel discussions scheduled for Monday through Thursday, Nov. 6-9. Topics covered are coatings, countertops, hardscaping and vertical, overlays and toppings, polishing, staining and coloring, and stamping.

Now through Nov. 5, admission for this year’s educational offerings includes an All-Inclusive Package at the bargain price of $435. The best deal going, the package allows participants access to 70+ hours of education including all workshops, panels and seminars, as well as admission to the expo. It’s the only package offered that includes admission to the expo.

Other packages offered are:

- Monday and Tuesday, education only – $310

- Monday through Thursday, seminars and panels only (no workshops) – $230

- Wednesday, education only – $100

- Thursday, education only – $100

- Wednesday and Thursday, exhibits only – $25

These packages will also be available on-site at higher rates based on availability.

To help promote networking and coating technologies education, Covestro is on board this year as a sponsor. Beginning at 5:30 p.m. on Tuesday, Nov. 7, education pass holders are invited to a sneak preview of the expo’s exhibits at an exclusive party complete with hors d’oeuvres and cocktails on the show floor.

The 2017 show will provide a convenient venue where concrete contractors, artisans, manufacturers, suppliers and distributors can rub shoulders with the biggest names and brands in the decorative concrete industry, pick up useful tips, discover new business strategies and enjoy extensive networking opportunities.

For more information or to register for this year’s event in Palm Harbor, go to www.ConcreteDecorShow.com or call (877) 935-8906.

About Concrete Decor Show

Concrete Decor Show is the leading educational conference and trade show dedicated to the decorative and architectural concrete markets. Now presented biennially, the Concrete Decor Show travels to different host cities and makes a lasting impression there by leaving behind the fruits of its workshops led by world-class educators. Featuring state-of-the-art exhibits and product demonstrations, the Concrete Decor Show attracts construction professionals from across the United States and around the world.