Here’s a trivia question, with history as the category:

Christopher Columbus sailed the ocean blue under the flag of Spain, a country ruled in the 15th century by the Catholic monarchs Ferdinand and Isabella. But do you know what nation Columbus called home?

Not that tough on the scale of trivia challenges, right? Columbus hailed from Genoa, now part of Italy.

People of Italian descent living in Memphis, Tennessee, proud of the Columbus connection to their heritage, took note that a local statue of the renowned seafarer and explorer would benefit from moving it to a site in Marquette Park in East Memphis, home to an Italian festival. So the Memphis chapter of UNICO National, an Italian-American service organization, proposed a restoration and relocation program for the statute.

City officials approved the proposal, and a fundraising campaign succeeded in generating the needed resources to pay for the project.

The UNICO group turned to Michael Hatcher & Associates, a Memphis landscaping and landscape design firm, to create a new setting in Marquette Park for the relocated statute. Hatcher & Associates, in turn, enlisted Baltz & Sons Concrete of Memphis to collaborate on the project.

Viva Italia!

Kevin Baltz, owner of the business, says Hatcher & Associates had a concept in mind for the project, but needed Baltz Concrete’s hands-on expertise to figure out how to make it happen.

The idea involved a terrace in an open green space of the park, where a map of the Mediterranean region would serve as the focal point for the Columbus statue. Italy, elevated above the sea and neighboring countries, would stand out.

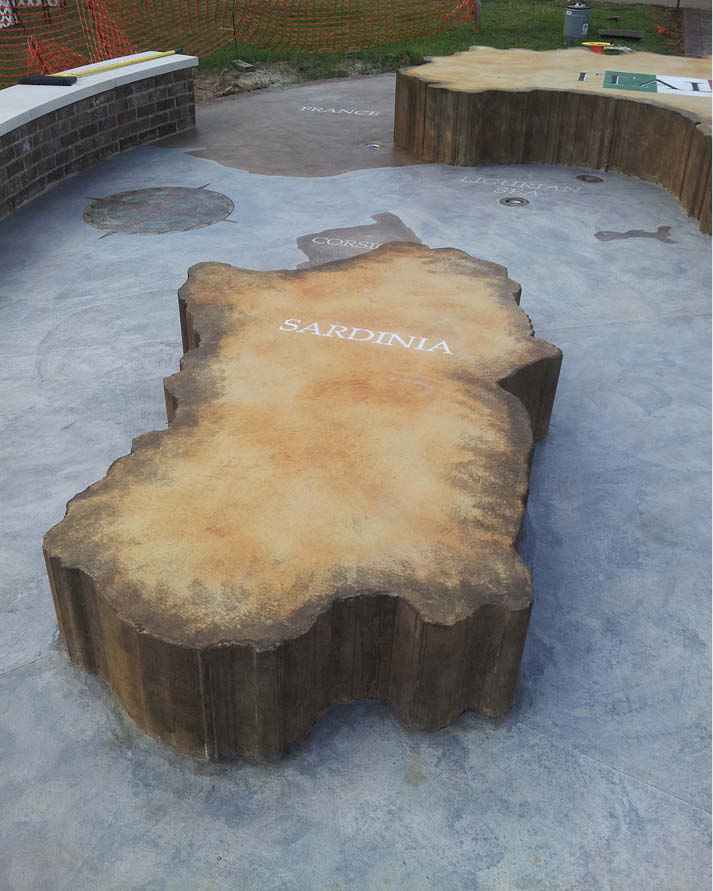

“They wanted Italy to be 18 inches higher than the rest of the map,” Baltz says. The islands of Sicily and Sardinia, part of the sovereign nation of Italy, would be slightly lower than the mainland, at 12 inches above the map’s flat surface.

The terrace, 35 feet in diameter, would include a concrete pedestal protruding from the middle of the mainland to support the restored Columbus sculpture.

Building the map’s mold

Building the map’s mold

Baltz Concrete brainstormed ways to execute Hatcher & Associates’ design, looking to devise a way to create this elevated work of art and the daunting challenge of assembling formwork and molding concrete to accurately portray the borders and coastline of the Italian mainland and Italy’s two islands.

For a blueprint, Baltz Concrete used Google Maps to print an accurate profile of Italy and the islands. Then the company purchased 10 large blocks of Styrofoam — each 4-by-8-feet wide and 24-inches thick — and started building the complex forms in their shop months before breaking ground on the site.

Baltz Concrete’s team came up with a method to draw the outlines of the countries on the forms. Using overhead-lighting projectors to cast an enlarged image, they traced the coastlines and borders onto the foam blocks, creating a massive 16-by-26-foot “puzzle” of forms.

Then came the hard part — cutting the molds to accurately reproduce the highly irregular, meandering edges along the seacoasts of Italy and the two islands.

Unable to find a large enough hot-wire cutter to slice through the 24-inch-thick foam, Baltz Concrete constructed a cutter specifically for this job. “We ended up building our own foam-cutting tool,” Baltz says, which included a plywood platform, a high-voltage transformer and an electrified hot-wire cutter.

“It was very tricky,” he continues. “The foam blocks were heavy and cumbersome, and so dense that you could only cut a couple of inches, then pause for a second or two for the wire to heat back up. It wasn’t a smooth operation. It was move, pause, move, pause.” A crew of four all working in unison was needed for this laborious and precise operation.

The job of cutting the forms — 865 inches total — took a full day, Baltz says. The cutting invention turned out to work amazingly well, with the heat of the wire melting the foam and creating a smooth edge.

Meanwhile, back at the park

To build the pedestal that supports the 12-foot-high bronze Columbus statue, the crew first constructed a hefty wood form — made from 1-inch plywood that was cross-braced with 2-by-4s every 8 inches. “That’s a substantial form for guys who typically do residential concrete,” Baltz says.

With the concrete base’s strength a priority, Baltz opted for a 4,000 psi limestone aggregate concrete, adding extensive rebar as well as cellulose fibers for hydration control and reinforcement. The 6-foot-tall form protruded above a 4-foot-deep footer to create a base that was “structurally sound and impervious to damage by vandalism,” Baltz says. The steel-reinforced pedestal also included a copper lightning rod for grounding the bronze statue it would ultimately support.

Once the pedestal base cured, the Baltz Concrete crew leveled the ground around it and delivered the finished foam forms to the site. Here, the crew built a rectangular “corral” to hold the foam-block forms in place, using plywood and 2-by-4s. The foam forms were then put in place.

Innovating once again

Realizing that conventional concrete release agents could chemically react and eat into the foam molds, Baltz Concrete used a homemade release mix of water and powdered laundry detergent. They applied this solution to the sides of the foam, using paint brushes and a pump-up sprayer.

Baltz Concrete consulted with local supplier Memphis Ready Mix and the Tennessee Concrete Association to determine a design-mix best suited for the application. They agreed on a modified 5,500 psi limestone concrete mix, reinforced with Solomon UltraFiber-500, a composition that flowed into the form’s highly irregular edges while resisting the formation of holes or blemishes.

To enhance the process, vibration was used, “which was probably overly cautious,” Baltz says, “but would ensure there were no air pockets, bubbles or honeycomb.”

Following the project’s pour and cure, the foam forms were laboriously pried from the concrete. Any residual foam was scrubbed away with wire brushes.

Baltz Concrete then turned its attention to the surrounding terrace, where a variety of textured stamps from Walttools/Contractor Source were used to produce a subtle slate texture. For the entry and a perimeter band, the crew used a London paver-stone pattern.

Each of the countries surrounding Italy was hand-drawn and scored into the surface, creating the sprawling scale map of the region. Each country was pigmented with a different color of Brickform acid-etch stain and Walttools water-based pigments, and the country names were engraved into the surface.

Baltz Concrete added the larger cities of Italy, a nautical compass rose and the Italian flag. A distressed-concrete finish was given to the pedestal base, evoking the old-world plaster finishes for which Italy is known.

In the end, Baltz Concrete succeeded in creating an enduring monument to Columbus, shown in the context of his homeland but looking outward to the wider world beyond the horizon. Visitors are encouraged to climb on and around the interactive concrete sculpture for a hands-on connection to the legendary seafarer’s homeland and surrounding Mediterranean region.

Project at a Glance

Project: Creating a concrete terrace in Marquette Park in Memphis, Tennessee, that features a multicolored map of the Mediterranean region, with Italy and its islands elevated, and a base and pedestal to support a bronze statue of Christopher Columbus.

Decorative Concrete Contractor: Baltz & Sons Concrete, Memphis, Tennessee. | www.baltzconcrete.com

Landscape Designer: Michael Hatcher & Associates, Memphis

Project Sponsor: Memphis chapter of UNICO National, an Italian-American service organization

Concrete Mix Supplier: Memphis Ready Mix

Other Key Materials: Solomon Colors UltraFiber 500 cellulose-fiber concrete reinforcement; Walttools/The Contractor Source textured stamps; Brickform acid-etch stain; Walttools water-based pigments

Scope of Project: Collaborate with landscape designer to develop and execute concept and construction of unique concrete installation honoring Christopher Columbus and highlighting his Italian heritage

Challenges: Producing molds shaped with large Styrofoam blocks to represent Italy and its islands with their rugged coasts; developing an electrified hot-wire tool to cut through thick foam; selecting materials for proper concrete composition; designing a base for the statue