What is the most important test when it comes to evaluating decorative concrete overlays? A case can be made that any test result can help better define how a product will perform, but when it comes to decorative overlays some tests are more meaningful than others. The test I find most important when looking at overlays, but one which is often overlooked, is tensile bond strength.

I was fortunate enough to be part of a group that recently completed a multiyear study that compared properties of various polymer-modified cement-based overlays. We looked at the impact of mix design, aggregate type and size, polymers and water-to-cement ratio on the final properties of various products. In many cases the results turned out as expected, but there were some surprises.

As the group compared notes and discussed the end results, it was no surprise that compression testing — material strength under load — was the result everyone automatically asked about. It also became evident that the second most important property the group was interested in, many times without even realizing, was adhesion — how well the overlay was bonded to the substrate.

So this got me thinking, which test is more important when looking at decorative overlays — compression or adhesion?

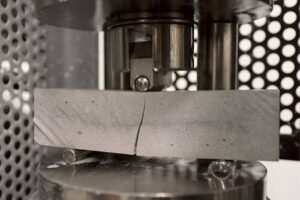

Compression strength

Before we can answer that question, we need to understand the basics of compression and adhesion testing in regard to concrete and overlays. Since ASTM International (www.astm.org) is the accepted leader for testing, we’ll stick with its test methods.

Compression testing is used to establish the crush resistance of a material — how much force can be applied straight down before the material fails. Decorative overlays fall under ASTM C109 – Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (https://www.astm.org/Standards/C109.htm).

A 2-inch cube of overlay is produced in a mold, removed, allowed to cure and then subjected to a pressure force until failure. The test is run multiple times, with the average being the accepted strength, usually measured in pounds per square inch (psi). In many cases, decorative overlays are compared to concrete when it comes to compression, with a target accepted range of 3,000-4,000 psi set as a benchmark.

Adhesion

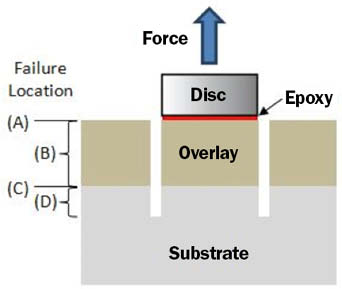

When we look at adhesion of overlays, ASTM C1583 Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method) is the accepted test (https://www.astm.org/Standards/C1583.htm).

The test, performed by applying an overlay to a substrate and letting it cure, determines the bond strength of the overlay to the substrate. A series of circular cuts are made through the overlay into the substrate to a designated depth. A metal disc is epoxied to the surface of the overlay and a special hydraulic press is used to pull the disc until failure. The results are measured in psi or mega Pascals (mPA).

As important, but often overlooked, are the location and type of failure. The types of failure range as follows (see diagram below):

(A) Epoxy to overlay contact point.

(B) Within the overlay.

(C) Overlay to substrate contact point.

(D) Within the substrate.

There are also combinations of these failures measured in percentages of each type. The best result would be if the epoxy failed before the overlay or substrate, but we don’t often see that in practice. The least desired result is to have the overlay fail at the contact point with the substrate, which would indicate poor material adhesion.

It’s interesting to note that decorative concrete overlays exhibit weak adhesion (typically below 500 psi) when compared to other industrial coatings and toppings, such as automotive paint and industrial primers.

Compression vs. adhesion

So back to our question — why is there such a focus on compression and not adhesion? I’m pretty sure the “concrete umbrella” effect is in play. Compression strength is the No. 1 property when dealing with concrete. Compression equals strength, which is what most people associate with long-term performance and durability. Since decorative overlays contain cement and the word “concrete” they tend to get lumped under the “concrete umbrella.”

In my opinion what is lost with the heavy focus on compression strength is that an overlay can be strong, but if it doesn’t “stick” strength doesn’t matter. The study showed that in many cases as compression strength increased, adhesion decreased. The focus for producers when developing overlays is the point at which strength and adhesion properties are optimized. This is not always going to be the material that promotes itself as the strongest.

When you consider the leading cause of failure with overlays is delamination, having a material with high adhesion strength can go a long way to offsetting that problem. I’d also like to note that high adhesion strength is not a replacement for proper surface preparation, which remains the most critical part of any overlay application.

Decorative overlays are hybrid materials that come in many formulations. Differences in polymers and mix design have a huge impact on the performance. A product that does well in Florida may not do well in Minnesota. There are also materials that are better suited for interior use. I encourage anyone who deals with overlays and coatings to do some research to better understand the common tests and which properties are most important for your application.