Brand new to North America, alternative construction material Tradical Hemcrete takes components that have been central to the wall-finishing crafts for centuries and puts a modern twist on them.

By combining a lime-based binder with a treated hemp shiv, the Tradical Hemcrete mixture provides an extremely sustainable, carbon-negative alternative.

“To my knowledge, it’s the only building material on the market in the entire world that is carbon-negative,” says Mario Machnicki, managing director for American Lime Technology, the North American distributor of Tradical Hemcrete.

According to a study done by the U.S. Green Building Council in 2005, buildings account for 39 percent of the country’s carbon dioxide emissions. So, a building product that not only produces zero carbon dioxide emissions once installed, but also actively reduces the amount of carbon dioxide in the atmosphere, is something worth taking notice of.

The industrial hemp in Tradical Hemcrete absorbs carbon dioxide from the air, just like any other plant does. When the plant is harvested (a hemp plant is full-grown after only 14 weeks), the carbon dioxide stays locked inside the plant. This carbon sequestration results in a product that, even in combination with the lime binder, takes more carbon dioxide out of the atmosphere than it puts in.

“Tradical Hemcrete locks up carbon within the structure of the building, because there is more carbon dioxide absorbed by the growing of the hemp than is released in the production of the Tradical binder,” says Ian Pritchett, managing director of Lime Technology, the United Kingdom-based manufacturer of the Tradical lime binder. American Lime Technology is a joint venture between U.S. Heritage Group Inc., which Machnicki is president of, and Lime Technology Ltd. that was formed for the express purpose of bringing Tradical Hemcrete, already popular in Europe, across the Atlantic.

“Tradical Hemcrete has a huge potential in any country serious about reducing carbon emissions from the built environment,” says Pritchett. “The U.S. market is now moving in that direction.”

Reducing carbon emissions isn’t the only thing Tradical Hemcrete has going for it, either. The material is 100 percent recyclable – if a Tradical Hemcrete building is torn down, the demolished walls could be spread on fields as fertilizer.

In terms of building with Tradical Hemcrete, it is quite a versatile product, offering two different methods of application that make it suitable for virtually any type of structure, new or preexisting. The first method is akin to concrete construction, where the hemp-and-lime mixture is poured over either steel or wooden structural members inside a temporary framework that is removed once the material has set. The resulting walls are breathable and extremely well-insulated. “We did a fire test on a 12-inch Hemcrete wall,” says Pritchett. “We placed one side of the wall against a furnace at 2,000 degrees Fahrenheit – after approximately four hours, you could still put your hand on the other side.”

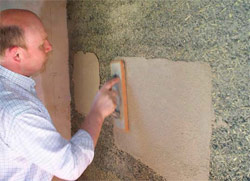

Tradical Hemcrete can also be pressure-applied over a timber, steel or concrete framework. This application method is not only more efficient, but also delivers the same insulating attributes

Tradical Hemcrete is also versatile from a design standpoint. According to the product brochure, “Tradical Hemcrete render and plaster products can be finished in the normal manner of such products, with finishes ranging from as-cast to a smooth finish. The hemp-lime products form an ideal substrate for the application of Tradical renders, plasters and decorative products.”

Although Tradical Hemcrete is currently “towards the top end of conventional construction costs,” according to the literature, there are several factors that should be considered when making price comparisons.

For one thing, when examined in terms of cost per square foot, Tradical Hemcrete is fairly competitive. And if you take into account the costs of the building over its lifetime, the material’s properties – insulation, energy efficiency, breathability and so on – ensure that overall, buildings that use Tradical Hemcrete stand to be considerably less expensive than those built conventionally.

The other cost consideration is the social status of one of the key ingredients – hemp. The industrial hemp used in Tradical Hemcrete is outlawed as a crop in the United States, despite the fact that we are one of the largest importers of hemp in the world. Unfortunately, industrial hemp has become caught up in conflict over its psychoactive cousin, marijuana.

Because industrial hemp is such a fast-growing, sustainable and versatile crop, Machnicki is confident that the U.S. ban on its growth is not long for this world.

“It’s only a matter of time before industrial hemp is legalized in the United States,” he says. “Americans are missing huge potential.”

If and when Americans are able to develop local supplies of hemp, the price of Tradical Hemcrete will come down. Currently, all of the hemp for the product is being imported from Canada.

In the meantime, Tradical Hemcrete is already finding a foothold here in the States. American Lime Technology has completed projects at an existing building on a Sioux reservation, plus two structures in Montgomery, Texas. The owner of the Montgomery project was so enthusiastic about the product, she became a distributor. Given all that Tradical Hemcrete has to offer, it’s easy to understand her enthusiasm.

(773) 286-0566

www.americanlimetec.com