|

|

Jobs always go best when you use the right tools. That certainly includes grinding and polishing. But when comparing planetary and rotary grinders, what’s the best grinder for your business?

A lot of it depends on what type of work you do. Do you typically open up concrete or polish it? Does your work lean toward removing heavy products, such as paint? Or tend more toward cutting down to the aggregate level of a terrazzo job?

There are grinders for both light and heavy jobs. Still, by adding or subtracting weights you can use both planetary and rotary grinders for many different projects. But overall, savvy contractors keep the variety of jobs in mind when developing their inventory of equipment.

Planetary machines plow through

At Seattle-based VIP Polished Concrete and Floor Care, much of its work comes from maintaining floors on a large scale.

“We take on a lot of larger polished concrete work for commercial, industrial and residential spaces,” says Jeze Harvey, office administrator/polished concrete assistant to company owner John Murphy. The company also handles stripping, waxing and floor maintenance for grocery stores, tanning salons, apartment complexes, hotel lobbies and more.

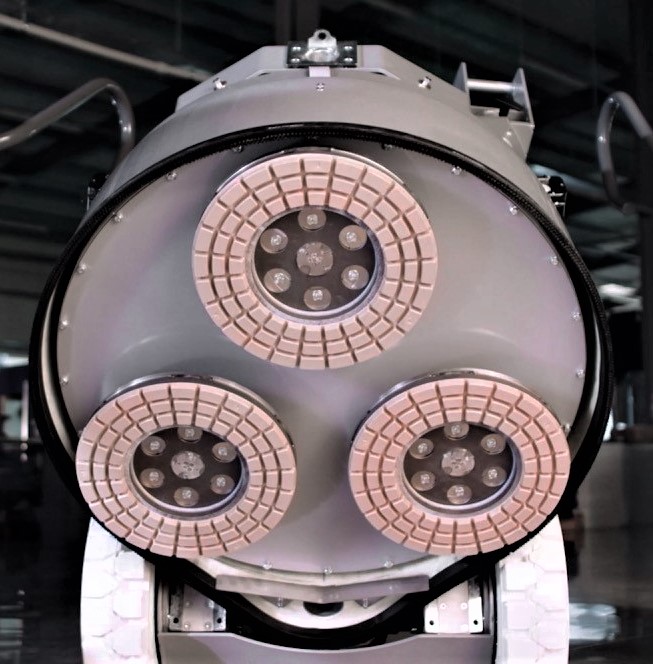

VIP’s grinder of choice is a 32-inch (L3213 GE) Lavina Elite machine from Hoschton, Georgia-based Superabrasive. A planetary grinder with three satellite heads rotating in the opposite direction of the main head, it suits less-intensive grinding tasks, as well as heavy-duty ones. Superabrasive offers the machine in electric and propane models.

“With our two 32-inch propane machines, we can typically accomplish about 6,000 square feet of polished concrete work in an open space in five days, even with concrete that may need some extra love due to previous wear and tear,” Harvey says. These larger 32-inch propane machines are heavier, she adds, creating an extra leg up for grinding capabilities on slabs. Although heavy-duty, they are user-friendly at the same time.

In addition to commercial, VIP also does some residential work. For those smaller jobs, it uses Lavina’s 25-inch model.

“Recently, when we completed a 3,000-square-foot home remodel with many fun angles, hallways, closets and smaller spaces, we chose to use our 25-inch electric Lavina,” Harvey says, because it’s more flexible and easier to maneuver “The base was also up on the project, creating a tad more of a challenge.”

Due to weight difference, “It takes a little longer but the 25-inch electric machine fits in most small spaces. With it, we can also get within a half-inch of the wall leaving not too much for the hand grinders to do,” she says.

Reliable rotaries perform

Franco Zanchettin, a partner in Amarillo, Texas-based Zanchettin Brothers Terrazzo & Tile Co., says much the same about his preferred grinder. Although with an emphasis on terrazzo, the company uses rotary grinders from Terrco Inc. in Watertown, South Dakota. Terrco first developed its grinders for the terrazzo business more than 80 years ago.

The rotary grinders, which use geared construction, are designed to put all discs on the floor. These consist of either one or two large discs or several small ones.

“I think we’ve got eight 701s (701-S series machines),” he says. “Then, we’ve got two mini-matics, which are the smaller, four-disc machines.”

As with Harvey, Zanchettin says the Terrco grinders provide power in a good size for his operation’s needs. Part of that is they’re very portable. However, with much of his business mix involving commercial properties, he, too, needs something to handle a lot of square footage. And the 701s fill that niche.

“Right now, we’ve got two 30,000-square-foot jobs going, and two 10,000 ones. Much of our work falls into that range,” he says. “The 701s are the most-convenient grinders, both power- and size-wise. And they fit through just about any doorway.”

Both can be just right

Although rotary grinders have a reputation of being too heavy for some jobs, while the planetary design is similarly thought to be too light for others, neither Zanchettin nor Harvey says that’s the case.

Lavina has many grinder models ranging from lightweight to very heavy, and the new Elite Series comes with integrated weights. This means you can increase or decrease grinding pressure according to the diamond step or type of job.

“We like the fact that they’re so durable that when you get to a high spot or when you get to really wavy concrete, it keeps going,” says Harvey Those in the know maintain this is a key advantage of planetary on polishing jobs.

“We’ve never had any issues because I can add weight or take it off. It depends where we’re at,” says Zanchettin about his Terrco grinders. “And it depends on the tooling we use, but we haven’t encountered jobs that are too big or too small for them.”

Training employees to use either type of machine isn’t problematic. Although rotary units have a reputation for being a little more difficult to learn to use, Zanchettin says it’s really a hands-on experience. That starts by making sure new employees understand the safety features of the machine. They also need to know how to hook up the vacuum system and attach the right tooling.

“We rarely run one machine on a job,” he says. “Normally, we have three or four. And we put the newer guy between the experienced people, with the most experienced guy doing the finish.”

A continual learning process

At VIP, Harvey agrees that training involves much hands-on learning. However, she observes there’s a bit of that on every project.

“Every concrete slab is different, and every concrete project is different,” she notes. “You can use the same machine on two different floors with the same diamonds and you might get different results. It really takes two or three different jobs for somebody to start to understand diamonds and what they stand for. Concrete is an evolutionary creature that’s constantly changing, which makes it a bit tougher on us on each job.”

So, if you want to buy a new grinder or grinders, what should you look for? Ultimately, it depends on what types of work you do – or plan to do in the future.

“I really recommend the 25-inch Lavina for anyone doing residential projects,” says Harvey. However, if your work mainly involves open spaces, the 32-inch electric or propane Lavina may better suit the task.

Invest wisely

For recommendations, Zanchettin puts it slightly differently. He advises anyone buying an electric grinder to consider possible problems with power availability.

“If you go with a 480-volt grinder, you won’t necessarily have power when working on new construction,” Zanchettin says. Subsequently, you might need a generator.

However, he adds, “Even a smaller Terrco machine will get the job done, even if it isn’t necessarily the fastest.”

The other thing he likes about his Terrco grinders is the manufacturer’s support that comes with them.

“We have one my granddad and my dad bought in the ’70s that we still use today,” he says. “Most of our maintenance issues have been wear and tear. If we have service issues we just get on the phone and ask for their help. Or we box up the machine and send it to them. And they get it back to us in a good amount of time.”

The bottom line, says Harvey: You get what you pay for.

“If you’re going to put money into it because you’re putting money into your future, you’re going to get a better machine when you’re not cutting corners,” she advises. “The same goes with diamonds. You have to pay attention to what really works. Sometimes they’re a little pricy. But often, the higher the price, the better the material.”

www.superabrasive.com

www.terrco.com

On the market for a concrete grinder?

Offered by Concrete Decor Store Lavina® 32 Elite Planetary Grinding and Polishing Machine

Lavina® 32 Elite Planetary Grinding and Polishing Machine

by Superabrasive Terrco 701-S Concrete Polishing & Grinding Machine

Terrco 701-S Concrete Polishing & Grinding Machine

by Terrco Inc.