People who know Ted Swaldo weren’t surprised last year when the Gervasi Vineyard & Italian Bistro began expanding.

Since opening in 2010, the family-run restaurant and winemaking operation in Canton, Ohio, has added a shopping experience, a conference center, lodging and a cooking school. During the same period, the demand for the company’s 15 different wines has grown to 16,000 gallons a year, despite a winery with only a 5,000-gallon capacity.

Enter The Crush House, which Swaldo describes as “a factory for making wine.” While it allows Gervasi Vineyard to increase its production capacity to 30,000 gallons, it also includes a 160-seat wine bar and eatery.

The factory description is quite appropriate, since, Swaldo says, “One of the things we were trying to capture is the look that we had built a restaurant in an old building.”

That’s where the concrete comes in. Not just on the floors, which would be natural for an old factory, but in the customer restrooms. There, Swaldo collaborated with Jason Geiser, owner of Orrville, Ohio-based Deco-Crete Supply, and Joe Gingerich, owner of the locally based G&M Concrete, to create sinks that leave guests talking.

Swaldo discovered both men independently of each other, although Gingerich and Geiser often work together when G&M is called upon to create the decorative and stamped concrete jobs that are its specialties.

“As I remember it, Ted came into our supply store,” says Geiser. “Somebody had referred him. He explained what they were doing and I thought our liquid metals would be perfect for the winemaking floor.”

While Geiser was making up samples for Swaldo to review, the owner of Gervasi Vineyard also contacted Gingerich. “I did a countertop for the plumbing contractor on the job (for his) outdoor kitchen,” Gingerich explains. “They were looking for something unique for sinks and the plumber suggested me.”

Soaring imaginations

Gingerich says that Swaldo initially considered standard concrete ramp-style sinks for all the bathrooms. Ultimately they installed 3-by-3-foot versions of them in the second-floor restrooms. However, for the main floor, the men unleashed their imaginations.

During that same time, Swaldo also had another meeting with Geiser at his showroom, and the Deco-Crete owner showed him a special sink he’d done for his own mother. “That’s when it hit me,” says Swaldo. “I said, ‘If you can do that shape, you can do a wine bottle.’”

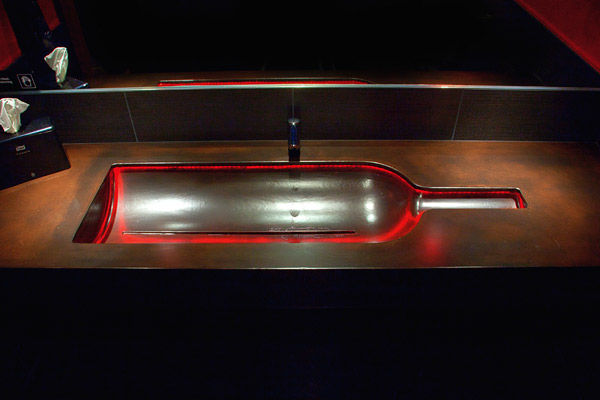

The end result: two 6-foot-long concrete sinks that look like wine bottles cleaved down the middle from top to bottom. If Swaldo and Geiser came up with the idea for the shape, Swaldo gives Gingerich credit for coming up with the idea of lighting them. “I originally wasn’t going to put in the LED lights,” says Swaldo, butafter Gingerich showed him some lighting ideas, it convinced him.

Gingerich explains the sinks required a custom-made mold. In order to install LEDs in them, he would need to create an overhang around the edge of the sinks where they could mount them. “They had to be waterproof and low-voltage,” Gingerich says. “They’re totally encapsulated and designed for underwater use, and because they’re mounted to the lip, if there are problems they’re replaceable.”

All the concrete sinks were cast in the G&M countertop shop, and Gingerich estimates he had two men working for approximately a week on creating the sinks. Installation of the half-bottles required a crew of eight.

“The sinks were more concept and planning than actual production,” he says. “That, plus finding a company that would make custom molds,” while trying to keep the cost in check.

They lit the ramp-style sinks in the second floor with integral fiber-optic lights. In all the restrooms, they installed red lights to pick up on the major color of The Crush House.

Industrial and safe

The color theme is carried over into the production area, where G&M installed a Deco-Crete brand red metallic epoxy, topped with Sparta-Flex, a polyaspartic concrete sealer from HP Spartacote.

“Ted liked the idea of having a seamless floor,” says Gingerich. “He wanted something that would take the heat, and that’s how we ended up with the metallic.”

For the restaurant area, Swaldo opted for a black acid stain. Gingerich says the idea there was to give it more of a warehouse look. That, too, received a topping of the Sparta-Flex floor coating. “It was also done during new construction, so the only problem we had was moisture being a little bit of an issue,” says Gingerich. “However, we had full access to everything.”

The floors each took a little more than a week to complete. Most of that time spent applying the sealer. In the production area, that also included a traction additive for safety. Deco-Crete’s Geiser says that’s a fairly accepted approach to coating floors where you prepare food.

One of the attributes of an epoxy floor is that you can make it seamless. Winery owners may find this attractive because it lessens their ongoing maintenance. “With tile you have grout joints where the bacteria can get in, but with this (type of flooring) there are no seams,” he says. With Deco-Crete’s Liquid Metals, “You pour it on, it self-levels, and it’s easy to clean, which makes it excellent for food safety.”

Swaldo agrees, saying the production floor still looks beautiful and is holding up well. However, he noticed some wear to the topcoat in the dining area where foot traffic is heaviest. “We like the look; it was a look we were hoping for because I wanted to make it look aged,” Swaldo says. “Maybe two or three years from now we’ll reseal it, but I don’t consider that a big issue.”

However, it’s the half-bottle sinks that really make the job for Swaldo. “In the restaurant business you have to have something that makes people say, ‘Wow,’ and restrooms are one of those things,” he says. “I love to hear people come out of the bathrooms and say, ‘You have to come see this.’”

Project at a Glance

Client: Gervasi Vineyard & Italian Bistro, Canton, Ohio

Decorative concrete contractor: G&M Concrete, Canton, Ohio | www.gandmconcrete.com

Decorative concrete supplier: Deco-Crete Supply, Orrville, Ohio | www.deco-cretesupply.com

Scope of project: G&M was hired to finish 10,700 square feet of flooring in Gervasi’s new winery and eatery, The Crush House, as well as provide concrete sinks for four customer restrooms.

Duration of project: G&M was on the jobsite for four weeks.

Tools and materials used:

Sinks: Hand-packed Duracast GFRC countertop system, Kemiko Black acid stain with Deco-Crete Color-Dye in Walnut.

Winery floor: Deco-Crete’s Liquid Metals Cherry Pie metallic epoxy and HP Spartacote’s Sparta-Flex sealer. G&M subcontracted a company to diamond grind both floors for prep; the contractor applied the colors and coatings with rollers and squeegees.

Eatery floor: Black Kemiko acid stain and Deco-Crete Color-Dye in Walnut; sealed with Sparta-Flex from HP Spartacote.