It is easy to understand the benefits of polished concrete — they are listed on everyone’s brochures. The word about polished concrete is out and we have done a great job of promoting the industry. By with all the different types out there, why choose burnished concrete?

It is easy to understand the benefits of polished concrete — they are listed on everyone’s brochures. The word about polished concrete is out and we have done a great job of promoting the industry. By with all the different types out there, why choose burnished concrete?

Polished concrete is growing. Great pictures of very well-done projects are all over the internet. The marketing has been great and many contractors are jumping on board. And the consumers are seeing a great product.

Along with this growth, something else has happened — polished concrete is evolving.

Polished concrete has categories

We have taken what was originally a full mechanically polished concrete system (six-plus steps) and started changing it. The term “polished concrete” has become a term that describes a flooring system family with its own subcategories. I don’t see this as a bad thing.

We have adapted to the needs of clients and designed different “forms” or “categories” of polished concrete. I have accepted this industry change and believe it’s a good thing. I now view polished concrete as more than a “one system fits all” approach. It’s a moving and evolving system that’s adapting to different environments.

I can imagine your scowling face as you read this and wonder, “What the heck is this junk?” But just think for a moment about all the projects you bid last year and lost. With some of them, someone simply underbid you to install the specified system. But what about those where the general contractor or architect wanted polished concrete but didn’t specify any one system? Others bid against you — and their bid offered a very different system than yours. They offered a resin polish, a hybrid polish or even a burnish and called it polished concrete. This is real and it is happening.

Full polish may not fit needs

I have been a stringent full mechanical polished concrete purist since the late 1990s. I never accepted any other form of polished concrete besides a full six-plus-step polish. Now in today’s market, I’ve realized polished concrete has outgrown that idea. Please don’t get me wrong. I still 100 percent believe a full mechanical polish is the best and truest form of polishing. But I find it difficult to force my ideals on every client.

Many clients want polished concrete, but quite frankly can’t afford it every time. What do you do? Do you bend the truth (and man, is there a lot of bending going on)? Do you tell them you can do it for less and then cut three steps and pile on the guard? Or do you prefer to educate your client about concrete polishing?

I recognize that a full mechanical polish may not fit every client’s needs or, more likely, their budget. So let’s explore some options. These options are types of polished concrete. However, they aren’t the true form of polished concrete and their benefits and aesthetics are different. Burnished concrete and diamond-burnished concrete are two categories I run into a lot.

Mechanically Polished Concrete

To start, we need a definition of true mechanically polished concrete. Polished concrete is the altering of a concrete surface by processing it with grinding, honing and polishing. These techniques use diamond-bonded abrasives to mechanically reduce the concrete surface’s peaks and valleys.

In combination with concrete densifying, coloring and sealing (or applying polishing guard), these methods are designed to achieve certain effects. These include resisting water and surface abrasion damage. This method also increases surface hardness, coefficient of friction and light reflectivity. In addition, effects also include a reduction in concrete dusting and in maintenance. Mechanically polished concrete also produces a very aesthetic and appealing flooring system.

Now we have a working definition of true polished concrete. As a result, we can compare it to burnished concrete and diamond-burnished concrete.

Burnished Concrete

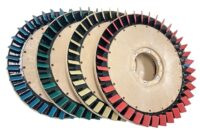

Burnished concrete is a system that uses a high-speed burnisher that spins at about 1,500 rpm to 2,500 rpm. The burnisher’s goal is to heat, melt and buff a chemical product on the surface. This action fills the concrete’s small pores with the applied chemical by melting and dispersing the product.

In the maintenance industry, the chemical of choice is typically a form of a wax-based product. In the polishing industry the chemical is a densifier product. Some prefer following the densifier with a guard product for additional shine and stain protection.

While burnishers are mechanical and spin under power, that’s the only similarity they have to a concrete grinder/polisher. Burnishers spin at a very high rpm and an aggressive pad may be capable of scratching the surface. However, there’s no true series of pads and not enough down pressure to process the concrete. The typical black, red, white or hogs-hair pads used to burnish aren’t designed to process concrete. They are designed to melt and buff a topical coating.

If using a densifier, the surface will acquire its benefits and will also have a glossy appearance. But burnished concrete won’t have the properties of a processed concrete surface that’s been grinded, honed and polished. Specifically, it won’t have the concrete’s mechanically reduced microscopic peaks and valleys, clarity, maintenance ease, additional flatness and longevity. On top of these factors, burnished concrete doesn’t look nearly as attractive as a mechanically polished concrete surface.

Diamond pad burnishing

Burnishing with diamond-impregnated pads add yet another dimension to this. The installers would use the same burnisher. However, they would use a pad with a sprayed-on diamond and resin mixture. This diamond-impregnated pad is typically available from 400 grit to 3,000 grit. This lets you do multiple steps of diamond burnishing with a powered, rotary machine.

When doing this with a concrete densifier you have a system using progressively finer diamond-bonded abrasives. You also enjoy the benefits that a concrete densifier provides.

Mechanical grinding with diamond tooling, densifier and multiple steps sounds like concrete polishing. However, it’s a system with no down pressure. It’s also one that spins at too much rpm to do any real grinding.

Diamond pad burnishing affects the cream’s very top layer and does little to reduce the concrete surface’s peaks and valleys. There’s not enough weight to create a deep enough scratch pattern to thoroughly abrade the surface. This is especially true if the FF (floor flatness) of the surface is poor. Starting at 400 grit, there’s no chance of anything besides a cream type of polish. A basic salt-and-pepper appearance is out of the question with diamond pad burnishing.

True mechanical concrete polishing can tighten and process the surface to create a shine even without densifier. But diamond pad burnishing needs the help of a chemical to create a form of a topical chemical polish. There’s some concrete processing happening but when you compare it to true mechanical polishing, it’s very little.

In conclusion

Different forms of polished concrete may be hard to accept and agree with. They are even more difficult to explain. I think we need to start with understanding that our market is changing. Polished concrete is adapting to fit the needs of clients and, unfortunately, their bank accounts.

By being able to understand and explain the different forms of polished concrete we can offer our clients different solutions. These solutions aren’t equal to the high standards to which we hold true to mechanically polished concrete. But they do fall under the category of polished concrete. Most importantly, they are options for a client who doesn’t want the floor to be covered by carpet and epoxy.

Questions from Readers

Question

I’m looking for a specification for concrete burnishing. Any suggestions on where to look? I’ve spent quite a bit of time online with no results. This is the best description for burnishing I’ve found so far.

Answer from Concrete Decor

Industry-approved language concerning burnishing polished concrete can be obtained from the American Society for Concrete Contractors (ASCC). The American Concrete Institute’s committee for Decorative Concrete (ACI-310) presides over a committee of the ASCC called the Concrete Polishing Council (CPC).

The two organizations work together to provide excellent resources to professionals on this topic and many others. You may purchase information from ACI or you can obtain this information through membership with the ASCC and its Decorative Concrete Council/CPC.