The first step to creating and processing a scratch-free polished concrete floor is to start by cleaning the floor you’re about to grind, hone and polish.

Make sure the grinder is clean. This includes the bottom of the machine, the skirt and the diamonds.

Inspect the surfaces of the diamonds you’re about to use for consistency in thickness, diamond reveal and coloration.

You’re ready to begin

- Grind the floor and then clean it with an auto-scrubber equipped with brushes and cleaner in the water.

- Again, clean the bottom of the machine and skirt.

- Put on a clean set of diamonds.

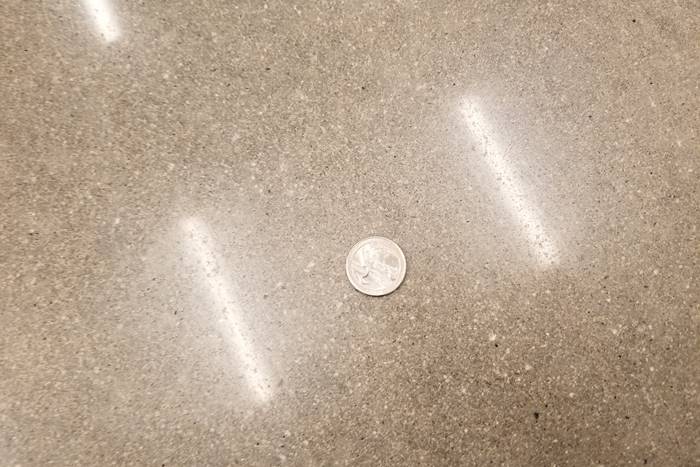

- After cleaning, inspect the dry floor.

- When a scratch is found …

Here’s the tip for creating scratch-free polished concrete

- Use a carpenter’s pencil (soft-graphite core) and circle the scratch or mark with an X.

- While processing with the next grit, the pencil mark will remind you where the scratches are.

- When the mark is gone, so is the scratch.

While processing, if you’re not sure all the scratches were removed:

- Stop the machine.

- Vacuum the area.

- Look and feel for valleys in the floor to determine whether the actual scratches are still there. If they are, use the pencil to fully mark actual scratches from end to end.

- Start the machine and process 90 degrees from the previous direction. You can hover as long as the machine keeps moving slightly. Leaving a machine in one place may cause other surface imperfections.

- Repeat process until both the pencil marks and the actual scratches are gone.

- If the scratch persists, put the previous set of diamonds on and repeat the above process only in that area.

- Remove that set of diamonds, attach the finer grit set and blend.

Continue to do this same process for each grit. By catching random scratches after each grit, you can bring a floor up to a high shine with confidence that there will be no surprises.

We’ve all been there. We think we have a beautiful floor and then we process with an 800 resin and we see what was lurking in the shadows. Use this process when it really matters. Unfortunately, every floor won’t merit this amount of detail.

Have more questions or a suggestion for polished concrete topics? Feel free to contact Jennifer Faller at [email protected].