It’s easier than ever for North American concrete producers to use CTS Cement Manufacturing Corp.’s belitic calcium sulfoaluminate (BCSA) cement instead of portland cement to meet public and private project owners’ sustainability goals for concrete. A Type III environmental product declaration (EPD) developed by Los Angeles-based Labeling Sustainability Inc. is available for the company’s two flagship brands: Komponent® shrinkage-compensating cement additive and Rapid Set® Cement.

It’s easier than ever for North American concrete producers to use CTS Cement Manufacturing Corp.’s belitic calcium sulfoaluminate (BCSA) cement instead of portland cement to meet public and private project owners’ sustainability goals for concrete. A Type III environmental product declaration (EPD) developed by Los Angeles-based Labeling Sustainability Inc. is available for the company’s two flagship brands: Komponent® shrinkage-compensating cement additive and Rapid Set® Cement.

This is the first EPD for BCSA and the shrinkage-compensating additive Komponent in the world.

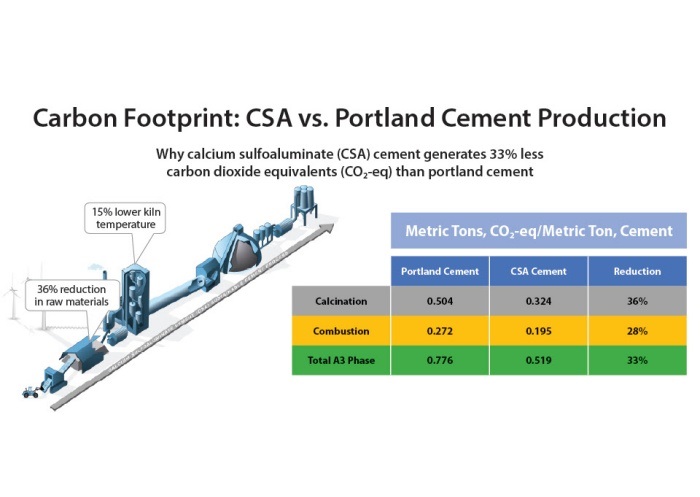

To earn this designation, an independent third party calculates a product’s cradle-to-gate global warming potential (GWP): the amount of carbon dioxide equivalents (CO2-eq) generated by the process of extracting raw materials, shipping them to a manufacturing plant, and turning them into cement. Compared to the Portland Cement Association’s industry-standard EPD for portland cement, BCSA cements generate 25% less CO2-eq per metric ton because they:

· Consume 20% less limestone per metric ton than portland cement, thereby reducing CO2-eq per metric ton.

· Are processed at a lower temperature (2,326° F) than portland cement (2,732° F), a 15% reduction that lowers fuel consumption.

Durability Increases Energy Efficiency

The two brands provide long-term as well as short-term energy savings. Because of its chemistry, CSA cement is inherently more resistant to common causes of portland cement deterioration: alkali-silica reaction (ASR), sulfate attack, and shrinkage cracking. Concrete made with CSA lasts much longer and requires much less maintenance than concrete made with portland cement. Factoring in the long-term durability of CSA cement concrete can lower a project’s carbon footprint even further in a cradle-to-cradle and/or cradle-to-grave analysis.

- Komponent® is an ASTM C845-compliant shrinkage-compensating additive blended with local portland cement to make Type K shrinkage-compensating concrete and grouts for transportation, tunnel, water and wastewater containment, industrial floor, and commercial building construction. In addition to thwarting curling and cracking caused by drying shrinkage, the additive enables project designers to significantly reduce or eliminate control joints.

- Rapid Set® Cement is an ASTM C1600-compliant cement that can achieve 4500 psi compressive strength at 1.5 hours. Unlike other CSA cements, it doesn’t require blending with portland cement or additives.

For these reasons, architects and engineers already specify Rapid Set-based products to earn a variety of U.S. Green Building Council Leadership in Energy and Environmental Design (LEED) credits for LEED Silver, LEED Gold, and LEED Platinum certification. The Type III EPDs further support a project owner’s efforts to use environmentally beneficial materials.

A wide and complex range of variables affects the environmental impact of every concrete mix. Our experts in CSA technology are eager to answer questions and help producers and project owners calculate the potential benefits of replacing portland cement with Komponent or Rapid Set Cement. Click here to start the discussion.

“The EPDs confirm what we’ve known for decades about the environmental benefits of using our products,” says CTS President and CEO Ken Vallens. “To address climate change, federal, state, and local government agencies are setting carbon-reduction and other green-building goals. Our technical experts are on call 24/7 to help architectural, engineering, and construction (AEC) firms and concrete producers understand how to use these EPDs to meet these goals.”