Operating conditions in the hydrocyclone process have a direct impact on plant availability and on grinding and flotation circuit efficiency. To help ensure continuously optimal hydrocyclone operation, Metso Outotec is introducing CycloneSense, a smart measurement system that provides direct, continuous, and reliable online monitoring of the hydrocyclone air core.

Operating conditions in the hydrocyclone process have a direct impact on plant availability and on grinding and flotation circuit efficiency. To help ensure continuously optimal hydrocyclone operation, Metso Outotec is introducing CycloneSense, a smart measurement system that provides direct, continuous, and reliable online monitoring of the hydrocyclone air core.

“In order to optimize the process, hydrocyclones should be run so that the fraction of water returned to grinding is the smallest amount possible. In order to do that, you need to know when you are approaching the limit of your hydrocyclone’s coarse discharge rate to avoid going too far and ending up with problems, such as roping,” says DSc., Professor Emeritus Kari Heiskanen, a well-known expert in the field and the author of the book Particle Classification. He continues: “CycloneSense smart monitoring technology allows you to see what is happening inside the hydrocyclone. It also helps to push the limits of the process.”

Unique technology

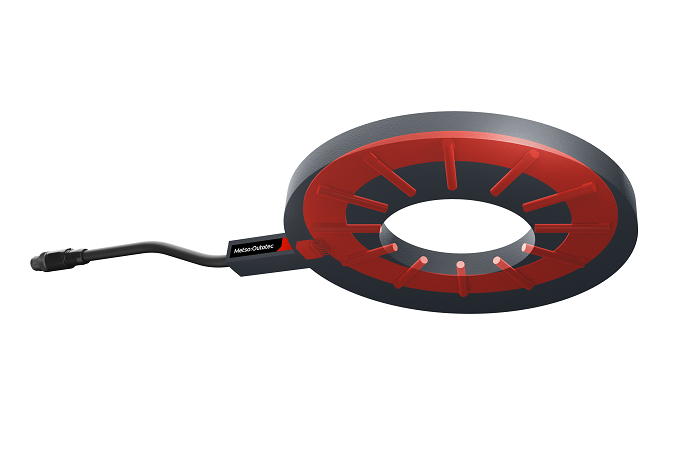

The unique CycloneSense smart monitoring technology allows you to visualize the performance inside the cyclone. It allows continuous online measurement of the cyclone’s air core shape, size, and location based on process tomography, thus helping to find and maintain the optimal operating point for the hydrocyclone. In addition, the measurement system helps to detect and prevent potential problem situations, such as roping, where the slurry is not properly separated and instead some of the larger particles are sent to the overflow and directly to the next stage of processing.

Combining CycloneSense with the Metso Outotec PSI particle size analyzer allows easy optimization of the cyclone cluster and grinding circuit. Metso Outotec’s ACT Cyclone Control and Grinding Optimization takes full advantage of the measurement data. It also provides significant and continuous benefits to customers.

The CycloneSense measurement system is available for new Metso Outotec hydrocyclones and any existing hydrocyclone installations. As an optional service, Metso Outotec also provides Life Cycle Services with remote monitoring.

Key benefits of CycloneSense

- Continuous, direct, and reliable online measurement of hydrocyclone air core shape, size, and location

- Helps to prevent problem situations in hydrocyclones, such as roping, and increases uptime and production

- Enables both automated hydrocyclone control and performance optimization of the system

- Provides valuable additional information for grinding optimization

- Simple to install, operate, and maintain with no moving parts

About Metso Outotec

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with their product and process expertise, they are the partner for positive change.

Metso Outotec commits itself to limiting global warming to 1.5°C with Science Based Targets. They have a 8th place ranking on the 2021 Global 100 list of the world’s most sustainable companies.

The company has its headquarters in Helsinki, Finland. Metso Outotec also employs over 15,000 people in more than 50 countries. Additionally, its sales for 2020 were about EUR 3.9 billion. The company is also listed on the Nasdaq Helsinki. mogroup.com, twitter.com/metsooutotec