Leave a mark. That sentence can mean different things.

Google that phrase and it tells you: “to have a lasting or significant effect.” Personally, it reminds me of the time my mother left my younger brother, Mark, at a Super America gas station in St. Paul when he was about 5.

After about five minutes of covert snickering at the thought of “leaving our Mark,” I reluctantly informed my mother we should probably go back and get our “Mark” back. After realizing I wasn’t pulling her leg, she hurriedly returned to Super America and found our “Mark” safe and sound.

Using locally made stencils

In the world of concrete, we constantly strive to leave our mark. The projects we complete are designed to last as long as possible. The Romans started using opus caementicium, or Roman concrete, somewhere around the second century B.C. The most recognizable structure made from that material was the Roman Colosseum, which dates to 70 A.D.

As time went on and language and mass communication developed, artisans started using engraving techniques to leave their mark. Fast-forward to the new millennium. One can witness the marks artisans have left in decorative concrete all over the world. One of the more popular ways to leave an individualized and unique mark on concrete is to use stencils.

Our company, Concrete Art, has installed numerous projects over the past two decades using stencils to create patterns, logos and pieces of public art. We performed one of our first pieces of public art in conjunction with Seitu Jones, a world-renowned artist from St. Paul, Minnesota.

Jones had been commissioned to install a few pieces of public art in the new concrete at the entrances to the newly remodeled St. Paul Farmers’ Market downtown. He came up with a series of designs which we had made into stencils at a local Fastsigns store.

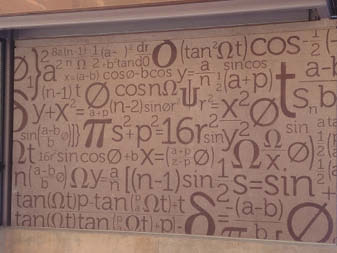

After adhering the stencil and peeling out the desired design, we proceeded to sandblast the concrete and then stain it using HLQ-125 from Sinak and tinting it with universal paint tints from Sherwin-Williams. This was back in the day, prior to the evolution of today’s multitude of UV-stable dyes. Above, you can see one of the works of art which has held up well for the past 19 years.

|

|

The Farmers’ Market

“The Farmers’ Market was my first time ever doing anything like that,” Jones says. “I remember laying out those designs in Photoshop. I had taken a class in the late ’90s to learn Photoshop. There was definitely a learning process to get a grasp on the capabilities of a different medium.”

Another project in St. Paul we worked on with Jones was the Rondo Commemorative Plaza. Again, Jones came up with a design — an artistic spin on a street map of Rondo, a prominent African American area which underwent a decades-long downward spiral due to racism, segregation and hatred.

Again, we used Fastsigns to produce the stencil and sandblasted and stained the design. While the Fastsigns stencils produced a favorable result, we experienced some difficulties with adhesion and user-friendly productivity.

|

|

Taking stencils to school

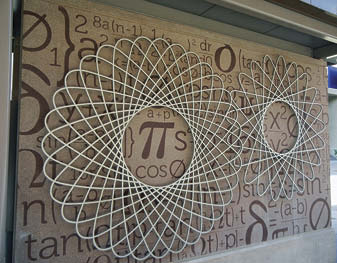

Still another stenciled public art project we worked on involved Jones and Brooklyn-based artist Nancy Blum. Jones referred Blum to Concrete Arts to help with some art pieces which would be installed at the light rail station outside the mechanical engineering building on the University of Minnesota campus.

Precast concrete panels were produced and then shipped to the Concrete Arts facility, where each piece was sandblasted and stained using stencils. As the finishing touch, once the pieces were erected on-site, Blum’s stainless-steel sculptures were fastened to the panels.

“I was very interested to find a way for the artwork of the spirograph sculptures in the design and the concrete pieces to be married,” Blum says. “And as an artist I’m always interested in the relationship between two-dimensional work and three-dimensional work, and the stenciling afforded me the ability to play with the two surfaces. The artwork is dimensional, so it casts shadows which make it come alive.”

Being in New York while her concrete pieces were produced in Minneapolis and the stencil work was completed in Wisconsin caused Blum quite a bit of trepidation, but once she saw the completed stencil work, she was thrilled with the outcome.

“It was one of the most exciting days I have had as a public artist,” she said.

Turning to stencils made for concrete

Eventually our company learned about Floormaps Inc. out of Bentonville, Arkansas. Owner and creative director Rachel Knigge-Bruce developed and designed a stencil production system specifically for the concrete industry. Her process allows for the multitude of difficulties concrete causes in both blasting and staining applications.

With a background in commercial art and advertising, she eventually did some freelance work for Ameripolish in 2004 creating stencils on a plotter/cutting machine she could access. In 2007 the relationship with Ameripolish expanded to a full-time position in advertising and training. Taking advantage of the multitude of dye colors Ameripolish manufactured, Knigge-Bruce was provided with a whole new canvas to show artisans how to “leave a mark.”

“I came from a printing background where we used multicolor designs,” she says. “And I figured out a way to essentially print on concrete.”

Knigge-Bruce eventually persuaded Ameripolish to make an investment in additional tooling to satisfy the growing interest in stenciling. She said the more she worked with concrete, the more she realized its untapped potential.

“At first, I didn’t realize I was creating something that was needed in the industry,” she says. “I was just trying to figure out the things which made the process easier. I convinced them (Ameripolish) to let me buy a cutting machine, and it just continued to expand from there.”

Recession slows progress

However, the approaching recession eventually led to her departure from Ameripolish. Knigge-Bruce decided to take some time off to spend with her family and figure out what was next on life’s agenda. In 2009, she founded Floormaps.

“The first year was pretty tough,” she says. “We only did about $16,000 worth of volume and we ate a lot of ramen noodles that year! But we have doubled in revenue every year since.”

A big source of increased income for Floormaps has been its relationship with Target. Knigge-Bruce says a polished concrete contractor in New York contacted her about four years ago when he was polishing a Target floor in Manhattan.

The floor was both old and beat up, with multiple flaws and a tile pattern which was ghosting through. She says the retailer was about to scrap the idea of polished concrete. They considered covering the floor with vinyl composition tile (VCT) instead. That was until the contractor and Floormaps came up with a stencil application which she named “Tribeca.”

“The Tribeca pattern was thorough enough to camouflage a lot of the defects in the floor,” she says. The company liked the pattern so much it started to use the Tribeca pattern in stores nationwide to differentiate areas in stores, such as the grocery and cosmetic areas.

The retailer also started to customize areas in certain locales. One of its stores in Manhattan, for instance, features a stained pattern that depicts a map of the Lower Eastside.

Right on Target

Knigge-Bruce estimates Floormaps has produced more than 750,000 square feet of stencil, with the Tribeca pattern averaging about 20 Target stores per year. The increased demand has naturally required her to increase the size of her operation.

“We couldn’t work out of my garage anymore,” Knigge-Bruce quips. “Now we have 14 employees working for us. We have worked hard and we have also been very lucky. It’s truly a blessing.”

The willingness of visionaries like both Jones and Knigge-Bruce to try different mediums has opened up a new way contractors can leave their mark with lasting and significant effects.