Vertical overlay finishes are being installed everywhere. They are the fastest growing segment of the overlay market, and that segment is growing faster than any other type of decorative overlayment.

Vertical overlay finishes are being installed everywhere. They are the fastest growing segment of the overlay market, and that segment is growing faster than any other type of decorative overlayment.

They account for millions of square feet of commercial buildings, concrete homes, retaining walls, fireplaces, columns, pillars, trees, theme parks, interior walls, ceilings, outdoor kitchens, showers and surrounds.

There are multiple types of vertical applications, but surprisingly, the steps are similar in all.

Exterior base materials can include ICF forms, T-mass, EPS, architectural Styrofoam and well-poured concrete, block and cement board. Interior base materials include architectural Styrofoam, polystyrene insulation, poured walls, block, ICF forms and drywall or cement board.

Preparation for installation

The surfaces must be clean and free of dirt and oils in order for the overlay to bond to the substrate. Etch with a manufacturer-recommended etcher and rinse, or use a diluted muratic acid solution, then neutralize with a diluted ammonia or baking soda solution and rinse. Every manufacturer will have specific preparation instructions. As with horizontal overlays, preparation is the most important step.

The surfaces must be clean and free of dirt and oils in order for the overlay to bond to the substrate. Etch with a manufacturer-recommended etcher and rinse, or use a diluted muratic acid solution, then neutralize with a diluted ammonia or baking soda solution and rinse. Every manufacturer will have specific preparation instructions. As with horizontal overlays, preparation is the most important step.

The other key element to preparation is taking the time to properly protect the area you’re working around. Plastic and coverings are needed on virtually every job.

With many overlays, adding a fiberglass mesh to the base coat is a good idea. Different regions have different specifications, and you will want to speak to your local building department officials. Manufacturers will also have specifications for best results. Mesh is inexpensive and easy to use. It provides extra stability and strength.

Proper preparation and proper process will achieve long-term success. In recent years, there was a trend for skipping steps. This trend is not a good long-term plan nor good for the industry. Manufacturers that recommended this have either closed or been bought out, and many contractors have had to move on to other industries. Long-term reputable craftspeople give the customer top-notch preparation, proper process and top-quality products to insure longevity and years of enjoyment.

Application

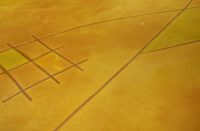

Standard spray applications are used for base coats, and surfaces are typically applied with a hopper gun. You begin by adjusting the sprayer tip size and air pressure for your desired appearance. There are many different textures that can be achieved with these simple adjustments. Move the hopper in a circular motion — continuous application is recommended for the best results. Typically, for exterior finishes, there is a base coat with fiberglass mesh, a second filler coat and a final finish coat. For interiors, an application of two coats is more typical. After material is applied, several trowel techniques can be used to create a variety of looks, commonly referred to as skip trowel, slate finish, knock-down and so on. An elastomeric product can also be used as a colored finish that provides elasticity and protection and far surpasses the life of traditional stucco.

Standard spray applications are used for base coats, and surfaces are typically applied with a hopper gun. You begin by adjusting the sprayer tip size and air pressure for your desired appearance. There are many different textures that can be achieved with these simple adjustments. Move the hopper in a circular motion — continuous application is recommended for the best results. Typically, for exterior finishes, there is a base coat with fiberglass mesh, a second filler coat and a final finish coat. For interiors, an application of two coats is more typical. After material is applied, several trowel techniques can be used to create a variety of looks, commonly referred to as skip trowel, slate finish, knock-down and so on. An elastomeric product can also be used as a colored finish that provides elasticity and protection and far surpasses the life of traditional stucco.

Vertical stamp overlays applied typically 1/4 inches to 3 inches are becoming the material of choice to get the look of stacked stone, boulder stone, brick, block, logs or hand-carved concrete. A base coat and wet polymer coat is always recommended for longevity. Again, it is applied with a hopper, sprayer or, if a polymer, a roller. If large overhangs will be applied, mesh is a good policy. Then, a wet coat is needed. This can be a thin layer of wet overlayment but is typically a diluted polymer coat. Most vertical stamp mixes have microfibers in the mix. Many contractors add additional fibers depending on application. The stamp material can be applied with sprayer or hawk and trowel. Artisans that do this like their mixes with varying slump consistencies, so most manufacturers have a built-in variance so you can have the product in a wetter or a dryer consistency. Apply material up to 3 inches thick. I have seen 6 inches, but I would recommend a fiberglass mesh with this. You will put material up differently depending on the stamp and look you are trying to achieve. Apply evenly for pattern stamps. For hand-carved surfaces, varying the thickness will optimize the realistic effects.

Mediterranean finishes and textures: When using a faux trowel, lift slightly in a semicircular motion. Use of file folders with jagged edges will give the illusion of cracks. Subtle colors, typically earth tones, will allow for a very elegant surface.

Temporal: With a faux trowel and a hawk, apply material to a dry surface. By lifting slightly for rough texture or placing your trowel at about a 5 percent to 10 percent angle you will be able to finish the surface smoother, leaving a multiple-dimensional textured look that’s smooth on the surface while rougher underneath.

Tamarillo: Take a small roller and apply material in a random motion, leaving some areas not covered. Allow to dry, then apply water-based stains, color or dyes. Apply multiple colors. Slide a round stippler brush in a straight line from floor to ceiling.

Wood grain: Apply your material with a Magic Trowel. Take your stippler brush from floor to ceiling in a slight wave motion. To make your knots, take a stiff paintbrush or the end of your Magic Trowel and in an egg shape twist your brush or squeegee a full revolution. Allow to dry firm, then tile-scribe lines into texture from floor to ceiling in random widths: 2 inches, 6 inches, 3 inches and so on. Then take the tile scribe horizontally and at different elevations install your end-of-plank seams. For the next step, a tile-joiner tool works nicely to install your round pegs. You can then take your tile scribe and install the cracks of the pegs and knots. Then, take some color and gel and dab random areas. Take stain or dye and, working from the bottom up, color and antique your boards.

Wood grain: Apply your material with a Magic Trowel. Take your stippler brush from floor to ceiling in a slight wave motion. To make your knots, take a stiff paintbrush or the end of your Magic Trowel and in an egg shape twist your brush or squeegee a full revolution. Allow to dry firm, then tile-scribe lines into texture from floor to ceiling in random widths: 2 inches, 6 inches, 3 inches and so on. Then take the tile scribe horizontally and at different elevations install your end-of-plank seams. For the next step, a tile-joiner tool works nicely to install your round pegs. You can then take your tile scribe and install the cracks of the pegs and knots. Then, take some color and gel and dab random areas. Take stain or dye and, working from the bottom up, color and antique your boards.

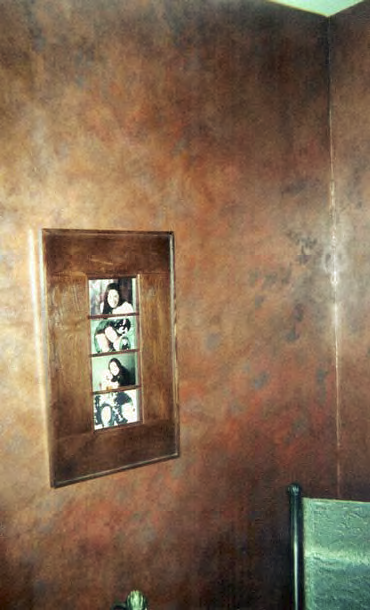

Faux marble: Take a micro or luster finish product and apply in a semicircular motion. Allow the curing process to start and burnish to your liking. Integral colors or topical color and stains are used. A very popular look is metallic, where you would apply a copper, gold, silver or pearl metallic topically for a base layer of micro-install, allowing the first layer to shadow through.

With vertical overlays, you spend less time and have fewer steps than with traditional faux products. You also end up with more durable, user-friendly products. Additional tools needed include a faux trowel, scrapers, spatulas, coating knifes, faux sponges, round and regular stippler brushes and a Magic Trowel. These coatings are applied from less than 1/16 inch to 1/4 inch. Customers will usually get multiple different faux applications on each project.

Coloring techniques and sealers vary with the looks you are trying to achieve. There are quality gloss, satin and matte urethanes, epoxies and sealers, so a realistic, finished product is easily achieved. Trainings and open houses on vertical applications are held throughout the world. Next time you’re out and about, take a look — vertical overlay finishes are everywhere. They may be on a living room wall, a tree at the zoo or a facade of a house or building. The possibilities are really endless.