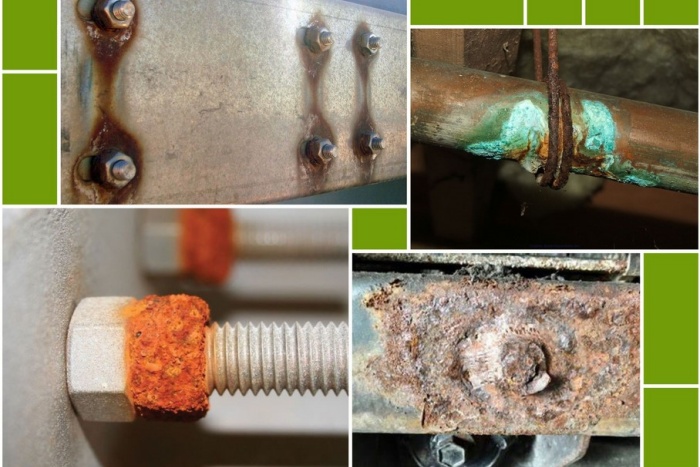

Galvanic corrosion typically occurs when two dissimilar metals are improperly coupled together in a corrosive environment. This common problem happens in almost every structure, including commercial roofing and facades.

The cause of galvanic corrosion is an electrochemical reaction between different classifications of metals rubbing against each other in wet or grimy conditions. This type of corrosion commonly occurs between aluminum and cast iron; copper and steel; and stainless steel and aluminum.

“Galvanic corrosion generally appears as clusters of chalky, thick mineral deposits that may turn rusty orange. It typically remains hidden on a building until there is an interior water leak that needs investigating,” says Rod O’Bannon, Manager of Western Specialty Contractor’s Sheet Metal Division in Kansas City, MO. “We typically see galvanic corrosion under a parapet cap or behind a panel system when builders use galvanized metal or screws to install aluminum or stainless steel. Galvanic corrosion can cause water infiltration of the building envelope which could lead to mold.”

O’Bannon recommends that property managers conduct a yearly inspection of a building’s roof and façade with an experienced specialty contractor to identify and address issues such as galvanic corrosion before they turn into major problems requiring expensive repairs.

Avoiding corrosion

One way to avoid corrosion is by using a single metal type throughout a project. However, that may not always be practical due to a metal’s availability or specific properties. When you identify galvanic corrosion, the specialty contractor may recommend placing electrically inert spacer materials such as rubber, plastic, nylon or neoprene between the two metals to separate them. They my also recommend isolating the dissimilar metals from moisture using specialized coatings such as bituminous paint.

“Using stainless fasteners when doing metal installations is also an option to prevent galvanic corrosion,” says O’Bannon.

For more information about galvanic corrosion, contact the Western Specialty Contractors branch location nearest you.

About Western Specialty Contractors

This company is family-owned and operated for more than 100 years. Western Specialty Contractors is the nation’s largest specialty contractor in masonry and concrete restoration, waterproofing and specialty roofing. Western offers a nationwide network of expertise that building owners, engineers, architects and also property manager. Their claim is that you can count on them to develop cost-effective, corrective measures that can add years of useful life to a variety of structures including industrial, commercial, healthcare, historic, educational and government buildings, parking structures and sports stadiums. Western has its headquarters in St. Louis, Mo. It also has 30 branch offices nationwide. Additionally, it employs more than 1,200 salaried and hourly professionals who offer the best, time-tested techniques and innovative technology. For more information about Western Specialty Contractors, you can also visit www.westernspecialtycontractors.com.