“During the late 1970’s and early 1980’s, industry experts initially introduced the Tapcon masonry screw to tap threads into concrete,” stated Bob Carlisle, President and founder of Concrete Fastening Systems, Incorporated regading the Tapcon masonry anchor. “The combination of the screw’s capacity to have threads hard enough to cut into concrete and to also remove the dust created during the application created an innovative design that revolutionized the concrete fastening business.”

“During the late 1970’s and early 1980’s, industry experts initially introduced the Tapcon masonry screw to tap threads into concrete,” stated Bob Carlisle, President and founder of Concrete Fastening Systems, Incorporated regading the Tapcon masonry anchor. “The combination of the screw’s capacity to have threads hard enough to cut into concrete and to also remove the dust created during the application created an innovative design that revolutionized the concrete fastening business.”

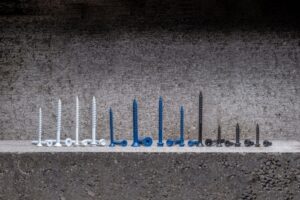

“The original Tapcon masonry diameters of 3/16” and 1/4” remain highly popular,” he explained. “Now added to these widely used fasteners are the large size diameter concrete screws (LDT) which are available in diameters of 3/8”, 1/2”, 5/8“ and 3/4”.“

Manufacturer

- Buildex, a division of ITW RedHead, manufactures the Tapcon brand masonry fastener in the United States.

Process

- The hole drilled into the masonry material is critical and must meet the tolerance specifications to meet minimum holding values.

- You must use carbide tipped drill bits that meet ANSI standards to drill the hole in the masonry, and you must also use them with a hammer drill that is set in the hammer and rotation mode.

- The 3/16” tapcon requires the use of a 5/32” while the 1/4” requires the use of a 3/16”.

Lengths

- The lengths of the Tapcon masonry anchor are the same for both diameters.

- The 1/4” comes in two additional lengths of 5” and 6”.

- The lengths available for both diameters are 1-1/4”, 1-3/4”, 2-1/4”, 2-3/4,3-1/4, 3-3/4’ and 4”.

Types

- The Tapcon masonry anchor comes in both a carbon steel. It has a Climaseal coating in a blue color and in the 410 stainless steel. The stainless steel variety also has a Climaseal coating in a silver color.

Embedment Depths

- The embedment depth of the Tapcon masonry anchor is critical both in the minimum and maximum embedment depth.

- You must install the Tapcon masonry anchor into the base material a minimum of 1” and the maximum embedment is 1-3/4”. Below the 1” minimum embedment depth the tapcon masonry anchor will not achieve required holding values.

- Embedment depths of more than 1-3/4” will create installation problems, such as when the Tapcon masonry anchor becomes stuck, unable to be removed or inserted further.

- The harder and the more abrasive the base material, the further from the maximum embedment of 1-3/4” should be attempted.

Head Style

- There are two different head styles that the Tapcon masonry anchors are manufactured: the hex washer slotted and the flat phillips countersunk.

- Both diameters come in both different head styles and require different size tools for installation. The 3/16” hex head requires a 1/4” nut runner; the 1/4” requires a 5/16” one. The 3/16” phillips flat head needs a #2-bit tip and the 1/4” needs a #3-bit tip.

- When measuring the lengths of the Tapcon masonry anchor, one measures the hex head from under the head. Then you measure the flat heads as an overall length including the head.

About Concrete Fastening Systems Inc.

Concrete Fastening Systems Inc. has been selling concrete fasteners for nearly 30 years from a fully stocked warehouse in Cleveland, Ohio. They also offer free, same-day shipping of every split drive anchor length and head style as well. They are available by ordering at www.confast.com, with product delivery within 1-3 days.