If it’s been said once, it’s been said a million times: There’s no limit on the possibilities with concrete.

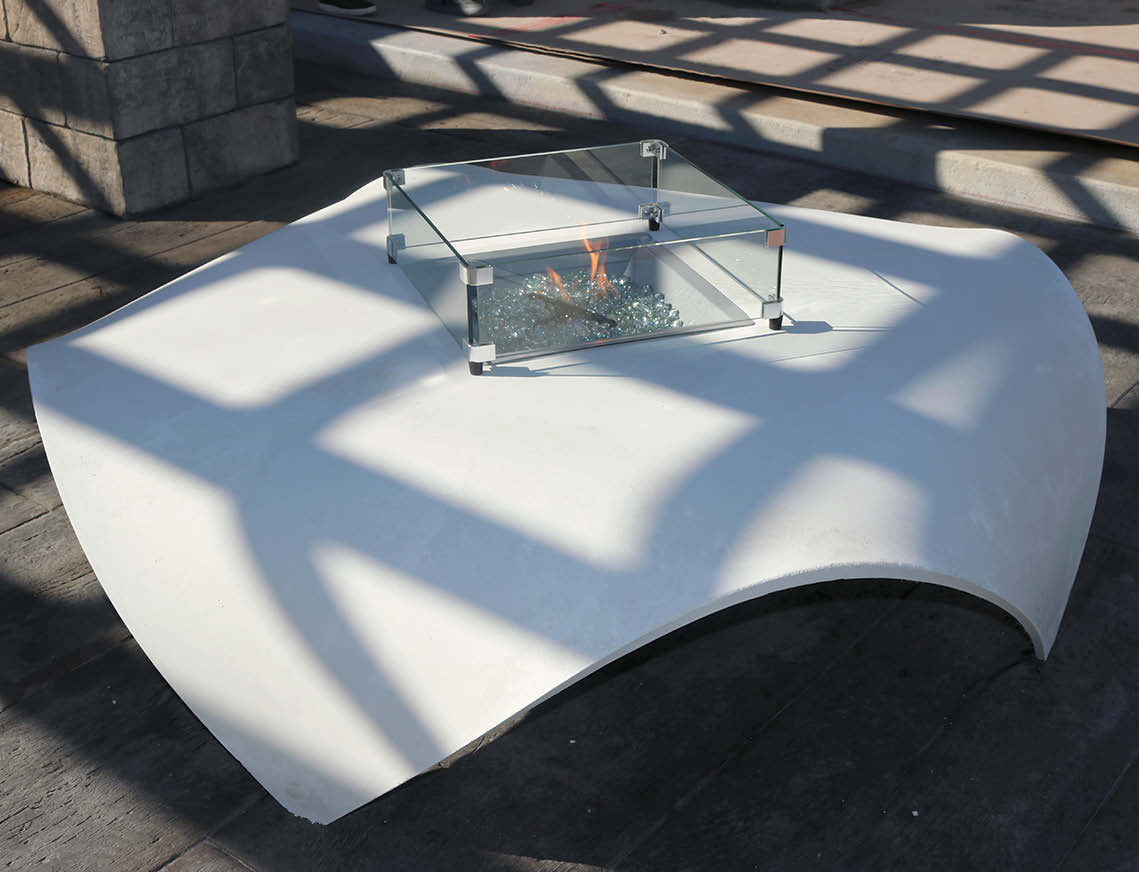

Take, for instance, what can be done with a simple 4-by-4-foot, 1-inch-thick urethane mold. Combined with concrete and four legs, you could use it to make a plain Jane square table. Add a twist of imagination and a flexible cement composite and you can shape that same mold — again and again with consistent results — into what its SureCrete creators call a warp table.

Part of SureCrete’s display at the 2020 year’s Decorative Concrete LIVE!, contractors created the warp concrete table on-site with XS Precast. This is a high-strength concrete countertop mix available in gray or white. With its fibrous components, the mix can be used to create thin yet very durable pieces that don’t require reinforcement. And speed also positively figures into the formula. They poured the table at 3 in the afternoon and they set it out for display at 9 the next morning.

To make the table even more appealing, they added a fire insert. The design could have just as easily included a recessed beverage cooler or even a small fountain, says Chris Becker, vice president for marketing and brand management for Fenix, the company that makes and markets SureCrete products. They could have also stained it.

The basic technique used to “warp” the table is easy to repeat, he says. “You wait for the mix to harden to a point where it’s firm but pliable. You then elevate the four corners about 12 to 16 inches and brace them. For the remainder of the curing process, it holds that shape.”

When they demolded and cleaned the table, they then sealed with XS 327. XS 327 is a two-component urethane that you thin with water and apply in multiple coats. The first coat is a 7:1 water-to-sealer mix. The second coat follows at a ration of 5:1. Finally, then a last coat used a 2:1 ratio. You should apply coats in a quick succession as the mixture dries quickly, Becker says.

The concrete table was such a hit that SureCrete will be adding a craftsman-inspired line of tools to its catalog. Becker says to expect the urethane mold to be available by May 1, 2020.

www.surecretedesign.com