Decorative grates made of cast iron look impressive. But too often, they’re also expensive, so they aren’t considered for any projects but those with the largest budgets. A company called Iron Age Designs hopes to change that.

Iron Age grates are manufactured using cost-efficient Danish technology, so they can be sold at prices that put them within reach of consumers, architects and contractors with modest budgets. “The technology allows us the flexibility to bring it to market at a much more competitive price,” says Iron Age president Mark Armstrong.

Cast iron stands up quite well to water, which makes it ideal for drains, he says. “Cast iron is naturally a very durable material. The Navy makes anchors out of it.”

Iron Age grates are made of recycled iron, making them environmentally friendly as well as weather-resistant.

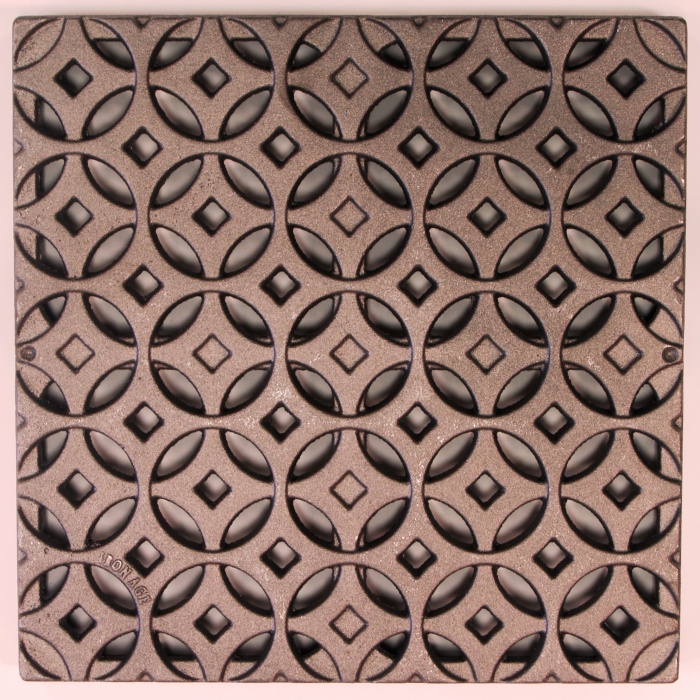

The grates are made to fit industry-standard trench drain bodies and catch basins from major manufacturers, and there are tree grates too. The pieces come in 12 unique, striking patterns with names such as “Locust,” “Paradise,” “Janis,” and “Carbochon.” With their artfully blended circles, ovals, waves and flourishes, these designs compare to those produced by expensive artisan foundries. “There is no reason for bland design,” Armstrong said in a news release. “Molten metal will flow into any pattern you pour it, (and) the vast majority of street furnishings are unimaginative and uninspiring.”

The vivid beauty of these grates is not surprising, as Iron Age’s founders are artisan foundry veterans who have produced and designed some of the industry’s more recognizable decorative grate patterns. Armstrong and his two partners, Craig Diamond and Dominique Watkins, left employment at another artisan foundry to start Iron Age. They wanted to devote more time and energy to pursuing this specialty niche, Armstrong says. The decorative grate line was formally launched at World of Concrete 2007.

The standard material used in Iron Age grates is cast gray iron per ASTM A48 CL 25 or better, and the standard finish is raw, as cast. Dimensions may vary slightly from casting to casting due to variations in the properties of different metals, and some designs are not available for some drain body sizes.

Iron Age grates can be retrofitted into existing installations or be purchased at the time of the original installation. The company also offers custom architectural castings in cast iron, aluminum, ductile iron and silicone bronze. All of the castings are ADA compliant.

Money and thought are lavished on surface applications like pavers, tiles and colored and textured concrete, but drains have been an afterthought, Armstrong notes. That oversight may be a thing of the past. Iron Age’s decorative grates make drainage a focal point.

Choose Decorative Cast Iron For Your Next Project

Offered by Concrete Decor Store 5" x 20" Janis Trench Grate

5" x 20" Janis Trench Grate

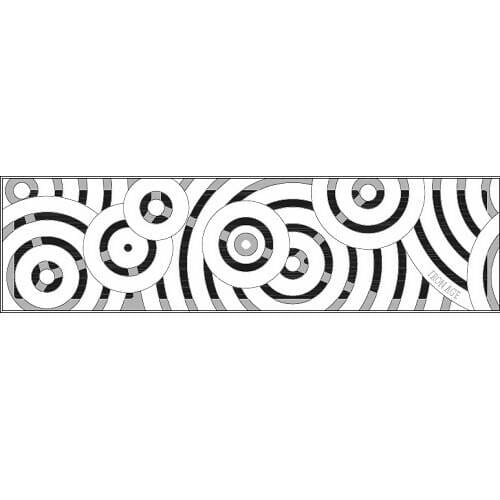

by Iron Age Designs 5.38" x 20" Oblio Trench Grate

5.38" x 20" Oblio Trench Grate

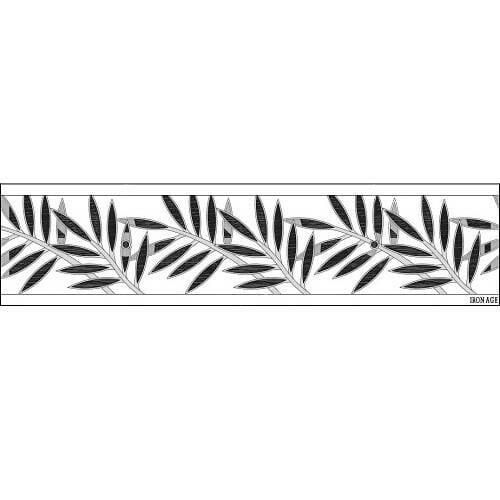

by Iron Age Designs 6" x 24" Locust Trench Grate

6" x 24" Locust Trench Grate

by Iron Age Designs