For many people, the federal Americans with Disabilities Act is so last century. P. Michael Fennessy, owner of Stampcrete International Ltd. In Liverpool, New York, isn’t among them, though. He holds two patents on a stampable concrete dome design that lets the blind and visually impaired navigate sidewalks and transit platforms.

The problem: “I see where some building departments and states take it seriously and enforce it. But, I’ve seen a lot of new construction where I don’t see this at all and I wonder how they’re getting away with it,” he says.

ADA was signed into law by former President George H.W. Bush in 1990, and among its many provisions is a guarantee of equal access to public facilities. The following year, Fennessy says, Chicago Mayor Richard Daley contacted him and asked if he could make a stamp that would create a detectable warning, meeting the specifications of the law.

“I remember I said to him, ‘Why me? I’m not the big guy on the block,’” Fennessy says. “He said to me, ‘Because your competitors say it’s impossible.’”

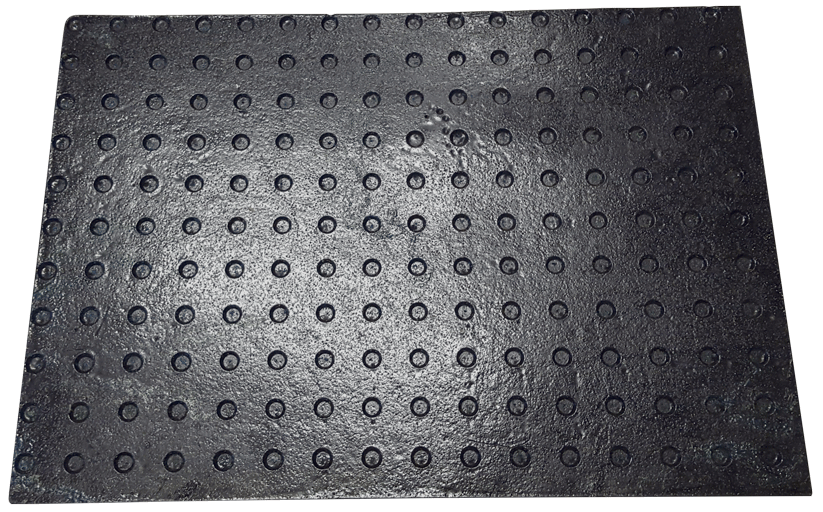

However, Fennessy says he understood their reluctance once he got into the process. He hired a machine shop in Syracuse, New York, to mill a 2-by-4-foot aluminum plate to the precise measurements required, plus an additional 1/64 inch “to allow for the urethane shrinkage.”

The design was accepted by both the federal accessibility board and the Chicago mayor’s office, which was pleased the work could be done for as little as $10 to $15 per curb cut. Fennessy patented his design, and says his only real competitor was another company with a much more costly composite design.

Better mousetrap or not, Fennessy ran into a problem with an accessibility board member over the issue of wheelchair access. As a result, the part of the regulation requiring a tactile warning for the visually impaired was put on hold for almost a decade. When it was reintroduced, it required the domes to be in rows, rather than on a diagonal.

Fennessy filed a second patent with the new design, but he says the new regulation, “didn’t have any teeth in it,” and so sales of the stamps have languished.

“I bet we don’t sell more than 30 to 50 a year, and it’s sporadic,” he says. “It’s usually when somebody has a new housing development and they may have 400 to 500 curb ramps to install. Then, it becomes a budgetary issue.”

In the meantime, Fennessy has also developed a way to retrofit existing curbs with a high-strength cementitious material and a liquid release agent, but he says none of it is generating much money.

“I just don’t believe the federal agencies are out there politicking like they did when it first came out,” he concludes.