Fab-Form Industries reports that the use of Helix micro rebar has dramatically changed their method of ICF panelization. Fab-Form Industries is a manufacturer of efficient building products for the concrete industry. They are located in Delta, British Columbia.

In the past, Fab-Form Industries manufactured the ICF panels horizontally — 12-feet long and two-blocks high. This configuration enabled them to progressively install horizontal steel as the components were built up on-site.

With Helix micro rebar, the ready mix company supplies and installs the reinforcing. This allows Fab-Form to manufacture panels sized for optimum site installation, not steel installation. Because of this, Fab-Form now manufactures panels 8-feet long and approximately 10-feet high, which increases contractor efficiency dramatically.

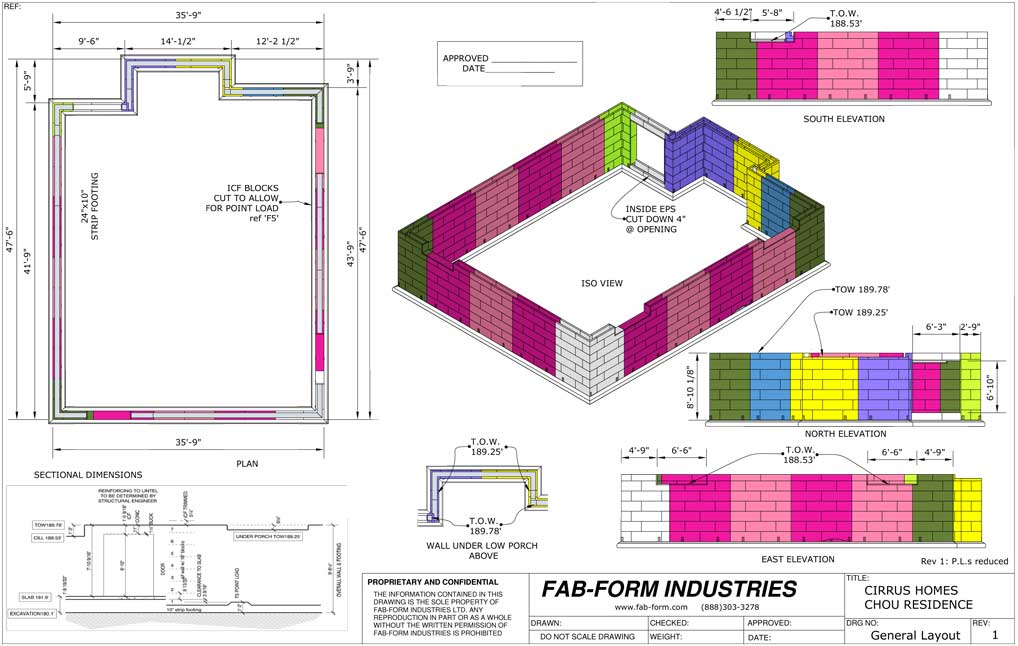

The Fab-Form monopour foundation is built in components with the fabric bag (which forms the footing) attached to the bottom of each panel. The different colored elements shown in the image above represent a separate component. Once the contractor has approved the working drawings, the manufacturing begins.

The working drawings allow the builder to carefully review of the top of wall elevations and final dimensions so that site errors and resulting delays and expenses are avoided. Even point loads in the footing are easily accommodated as shown in the drawing above.

Monopour panels are delivered by truck to the jobsite. A drainage layer across the site prevents ground moisture from entering into the concrete. String lines and batter boards are used to align each panel.

The website includes a detailed video, panel drawing and photos of a recent installation of the new method of panelization.

The Fab-Form Monopour System uses the ICF block itself to form the footing, thereby eliminating all footing forming lumber, stakes, cold joint and double pour. Monopour Supports suspend ICF blocks above the ground at the required footing height. Fastfoot is attached to the bottom of the ICF blocks to form the footing. Sewn corners and T-junctions increase speed of site installation dramatically. Fastfoot is GreenSpec listed and LEED point contributing.

(888) 303-3278 ext. 102