Existing Conditions: Staten Island Ferry sees thousands of patrons daily and needed a floor that could withstand that kind of traffic. The tile they had in place was chipped, cracked, and missing in a handful of spaces.

Preparation of existing condition: Since many of the tiles were delaminated we had to sound out the floor to ensure these tiles were in fact well bonded to the substrate. After ensuring the bond and condition of substrate we began diamond grinding the tiles to remove any laitenance and establish a mechanical profile. The final step of the prep involved our team installing 1/4" keyways at all terminations to ensure system thickness while creating a seamless edge.

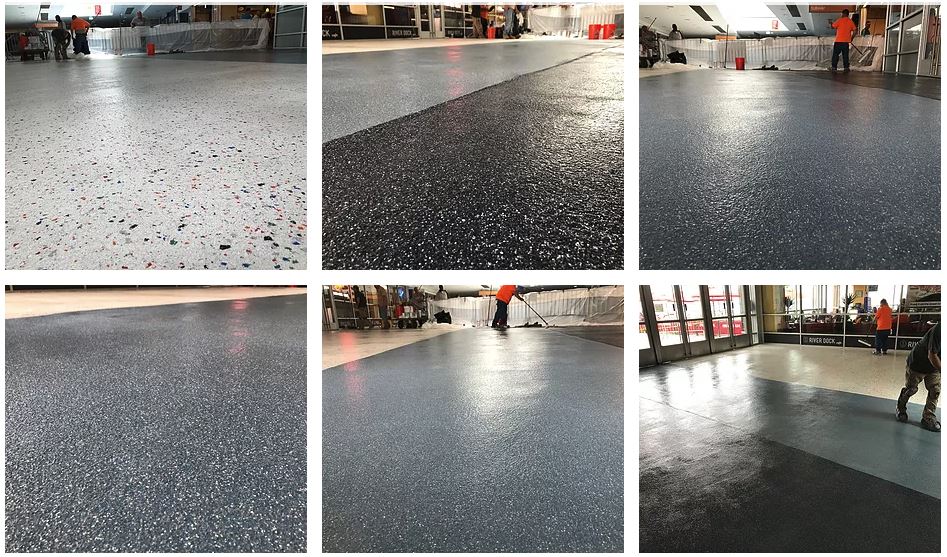

Products Installed: Step one of the installation was to apply the system water proofer/primer GP 3555; elastomeric epoxy. Next our team applied the system base-coat of Fastop 12S breathable urethane cement applied at 1/4″. Before allowing the floor to cure we broadcast 40/60 mesh sand into the base-coat for added compression strength to help the floor hold up against the immense foot traffic load. Once the excess sand was swept off we laid down a coat of GP 3561 100% solid epoxy resin to give the vinyl epoxy flake something to adhere to. We than repeated the process with a second coating and broadcast. The final step was to apply two coats of GP 4850 polyaspartic to seal in the broadcast and to add even more mechanical strength to the floor ensuring its longevity.

Conclusion: This installation was unique due to a number of different factors. Staten Island Ferry remained functional during this installation, our team worked closely with SIF to come up with a game plan to make this work. The ferry remaining open also meant that it was imperative that we created no dust or debris which could cause harm to the daily passengers. On the design end our team was tasked with coming up with a vinyl epoxy flooring system that could not only hold up to severe traffic but would also match the aesthetic of the tiled areas that we were not replacing. In the end we were able to provide SIF with a beautiful vinyl epoxy flooring system, that will hold up for years to come while providing, added stain, slip, and chemical resistance.