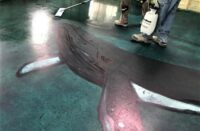

If World of Concrete 2011 was any indication, the polished concrete market will again see substantial growth in the coming year. It has become pretty clear that polished concrete is the hot market in decorative concrete right now. There was no shortage of equipment and chemical manufacturers touting the latest and greatest at the show, with each making a case for why their system was the best option on the market.

Unfortunately, like almost every other previous hot decorative trend, the polishing market tends to move faster than the technology. It seems that polished concrete has become the new siren’s song, so appealing that anyone getting close enough to hear it ends up getting caught up in the allure of easy money. Well, if sounds too good to be true, it usually is!

Yes, polished concrete is the hot market, and yes, we are seeing more of it being specified in large applications, but as with any other technical application, there is much more to polishing than meets the eye.

Over the last few years I have noticed a rise in the number of complaints and issues dealing with polished concrete. These issues range from misunderstanding the market all the way to improper application. The biggest issue by far that I come across is the misconception in the marketplace that the polishing process is easy. The idea that buying the equipment is the hardest part of getting into polishing could not be farther from the truth.

Don’t get me wrong — I am all about diversification and expanding into new markets, but at the right pace and with the right education. The new polishing contractor soon finds out that polishing concrete is more than dragging a big machine across the floor. Little things like blending the polish from main floor to walls, corners and edges all of a sudden become big issues.

The other reality that seems to hit home after the fact is the need to truly understand the science of concrete. Questions must be answered like: How flat is it? How hard is it? How will the diamonds cut into it? And how do you deal with cracks and bug holes?

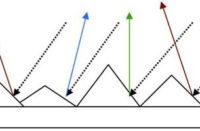

Speaking of diamonds, which type to use and when to switch to the next grit level are two other areas that are often misunderstood by the novice polisher. The operator running the polish machine needs to be as much an artist as a technician.

Another major area of confusing or bad information comes on the chemical side of the polishing industry. There is no shortage of companies offering penetrating sealers, densifiers and hardeners. First, one must understand the chemistry behind what these chemicals do and the part they play in the polishing process. The market offers sodium-, lithium- and potassium-based penetrating sealers. While lithium has a smaller particle size and provides deeper penetration, sodium and potassium densifiers tend to cost less. All three types perform the same basic function — reinforcing and strengthening the top layer of the concrete through chemical bonds.

A note of caution! I have recently seen some companies promoting high-end lithium-based products at very low cost. After looking into this I found that these chemicals were mostly sodium- or potassium-based systems with only a splash of lithium. As I have written previously, the decorative industry tends to market aggressively and can play loose with the facts. Always do you research and buy from a reputable source.

Lastly, answers to the question of when to color during the polishing process seem to run the gamut from early to late. In my experience, the top-end applicators who have been polishing for a long time keep this information close to the vest. What I was able to find out was that no two systems were alike, and each individual polishing company settled on its own formula of where, when and how when it comes to coloring during the polishing process.

There are numerous other misconceptions in the polishing market, more than can be covered in this piece. The key point I am trying to get across is that appearances of simplicity can be misleading. I can see where the idea of purchasing an expensive polishing machine can motivate an “I can do this now” attitude, while in reality buying the machine is the easy part.

Polishing decorative concrete is one of those trades for which you need to be an expert in many different disciplines — concrete, chemicals, color, and finally, the actual polishing process. I can’t stress enough how education and experience are critical. Take advantage of training schools offered by equipment and chemical manufacturers, or take one of the many classes on polishing at and upcoming Concrete Decor Show.