Many beginners approach color from a simplistic viewpoint: They pick a color from a chart and assume the end result will look exactly like that. “They don’t understand how concrete changes as it’s manipulated,” says Jeffrey Girard, P.E., president of The Concrete Countertop Institute.

Texture – how concrete is finished – is one of many elements that affects the way we perceive color on decorative concrete surfaces.

For example, the reflectivity of a surface helps determine the final color of integrally colored concrete, says Rich Cofoid, national sales manager for Increte Systems. “For the most part, the smoother the surface, the more reflective it is, and the more reflective, the lighter a color will look.” Polished concrete produces the most reflective surface, followed by steel-troweled and float-finished. Broomed concrete is the least reflective of the bunch.

If you ask Todd Rose, owner of ToddRoseConcreteTraining.com, based in Charleston, S.C., about color and texture he’ll tell you it all starts with porosity. “The more porous the concrete, the less vibrant the color.”

Overall, the more textured the surface, the more the color will change depending on the viewing angle. You don’t see a consistent color on a rougher slab like you would on a steel-troweled and sealed floor.

“Everything we do to concrete affects how clients see color and the way it appears to the eye,” says Girard. How concrete is troweled affects how it cures, and that affects its shading. If you trowel too hard, it burns the surface and darkens. If concrete is polished, a thin layer is removed, revealing some degree of aggregate.

The color saturation level, the intensity, the shading, the sheen and the texture all contribute to the outcome, Girard notes. “Concrete’s appearance is like one rope with many strands. And the individual strands influence the final result.”

With a little imagination, you can put these factors to work.

Get creative with broomed finishes

Brooming integrally colored concrete can add more than texture. It can create the illusion of different colors.

For instance, there’s a reddish-colored raised median dividing a major roadway in Boulder, Colo., where broomed sections lie between smooth-troweled patches, says Chris Sullivan, vice president of sales and marketing for ChemSystems in Houston. “When you drive by, the color shifts up and down. It really denotes the median itself and brings attention to it.”

However, when brooming integrally colored concrete, applicators should have experience, says Doug Bannister, owner of The Stamp Store in Oklahoma City. “A common mistake with crews unfamiliar with colored concrete is to wet-broom in the same manner as they do with gray concrete,” he says. “But this washes out and streaks the color, causing the project owner to be disappointed and even feel cheated.”

“An excessively wet broom will change the water-to-cement ratio and give you blotchy colors,” agrees Bart Sacco, president of Concrete Texturing Tool and Supply in Throop, Pa. “Wipe off the excess water so when the tool touches down it’s not soaking wet.”

Stamped concrete and color

If you think stamping concrete doesn’t affect color, think again. You’ll get less highlighting color on lightly textured surfaces and more pronounced color with aggressive finishes.

Bart Sacco recalls a recent job where the client visited his showroom and selected a slate green with a light gray release. The combination was displayed on a very flat, smooth 2-by-2 slate pattern sample. However, the stamp she chose for the roadway and traffic circle installed on her property was a very chunky 3-inch-by-6-inch cobblestone.

When the job was completed, she initially refused to pay, claiming the crew had used the wrong colors. “The colors appear different because the light gray release took to the smaller cobblestones much differently than the smoother slate,” Sacco says. “I also explained to the architect that the sun reflecting on the cobblestone slab made it look different (than the sample in the showroom).”

She accepted the third-party review and finally paid the crew. “The only thing they did wrong was they didn’t make a test pour,” he says. “You should always do a job site mock-up.”

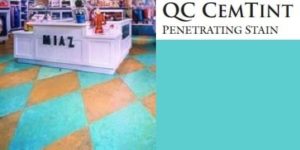

Stains versus dyes

Different methods of coloring concrete are affected by finishes differently. Acid stains generally look darker on broom finishes than on smoother, steel-troweled surfaces. That’s because “a heavy texture has more surface area and less reflectivity,” says Rich Cofoid. Textured slabs won’t have as much acid stain marbling as smoother surfaces, notes Chris Sullivan. “Stains will saturate rough broomed surfaces in a more even manner.” Smooth concrete, however, consists of areas with varying degrees of porosity, producing the classic marbled look.

Because acid stains chemically react with the paste in the concrete, he notes, you’re at the surface’s mercy when it comes to color control. Applicators using acetone-based dyes and water-based stains have more control over color regardless of the texture. If you want the surface darker, put down more product. If you want it lighter, use less.

Controlling the final outcome

Admittedly, when it comes to integral color, cement variations and sand color will have more of an effect on integral color than texture does. Slag and fly ash will alter the final color, as does water. “The more water you add to the concrete, the more diluted the color becomes,” Cofoid says.

Still, even with all these other factors impacting integral color, the finished texture is clearly a factor, and it is with stains and dyes too.

So how can a colorist get a handle on upping the skill level associated with pouring and finishing concrete? “I would love to say we’re winning the war but the truth is people are looking for something cheaper and faster,” says Rose. “That’s why I often get hired to stain a slab but don’t get to pour it.

Even so, he says, consumers’ expectations have risen when it comes to the end result, in part because of the Internet. “The days are long gone when the stain contractor can blame the guy who placed it. Instead, you have to be versatile enough to deal with issues before they come up. In order to succeed you have to be proficient in multiple products. The days of being a one-trick pony are over.”