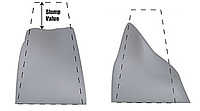

For official results, slump is measured with a metal cone made explicitly for that purpose. There are certain procedures that must be followed to conduct a standard test, which are outlined in ASTM C143, the Standard Test Method for Slump of Hydraulic Cement Concrete. The four-page document can be purchased online from ASTM International.

Bob Harris, president of the Decorative Concrete Institute in Georgia, adds that for reliable readings it’s key to conduct tests on a level base made out of a nonabsorbent material such as sheet metal or Plexiglas, not wood.

Most decorative concrete contractors don’t conduct standardized tests when pouring driveways, pool decks or the like. For practical purposes, most seasoned contractors can tell if the slump is right when they see the concrete coming down the chute. Harris can go one better: “I can tell if it’s dry or wet just by listening to the truck turning,” he says with a laugh.