Verti-Crete

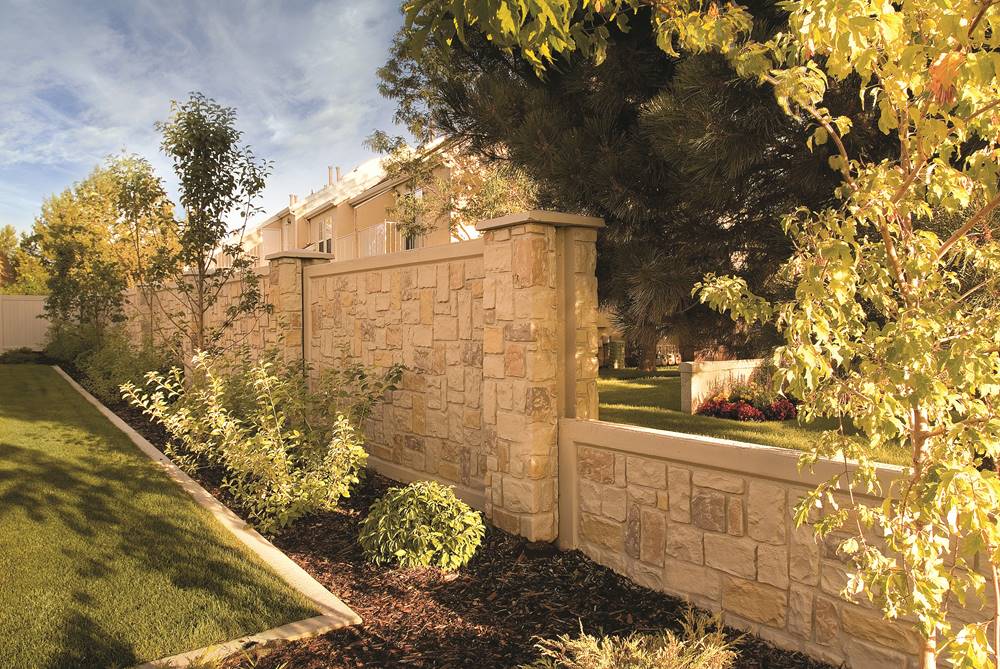

If you’re going to erect a long molded concrete wall, you’re going to be doing a lot of vertical pouring, and one of the most cost-effective ways to do that is with concrete forms and form liners like the Panel Stacker System. Made by Verti-Crete LLC, the precasting assembly turns out seamless, double-sided walls and posts with the look and feel of real stone, and can do it several pieces at a time.

The system is a steel-frame structure that holds a row of steel and polyurethane molding sheets. Several panels are poured at once, while the outside frame holds the molding in place, eliminating the need for tie rods that leave ugly holes. This precast system produces higher quality molded walls at faster speeds than castin- place systems, and it does more with less space than traditional precasting steel beds. The System is more expensive than cast-in-place equipment, but if a contractor is going to be pouring a lot of decorative precast walls, the assembly may well be worth it.

For more information, visit www.verti-crete.com or call (801) 571-2028.

Stone-Crete

It makes sense, given their name: Stone-Crete form liners are molded from natural stone surfaces.

The liners are part of a cast-in-place concrete wall creation system from Increte Systems. They fit together on all sides to create non-repeating patterns. They duplicate the color and technical specifications of hand-laid stone at a fraction of the time and cost it takes to lay down actual rock.

Stone-Crete liners are made of highly durable urethane and can be used multiple times. Together with Increte acid stains, integral colors and clear-seal coating, they constitute a cast-in-place decorative concrete wall system that can be mounted on any standard forming system. They come in 10 deep relief patterns, including “Dry Stack,” “Navajo,” “River Rock,” “Wood Plank” and “San Luis Obispo,” and are available in an assortment of filler sizes. Certain liners can be used when molding corners or corner posts.

For more information, visit www.increte.com or call (866) 342-8760.

Arch-Crete

Arch-Crete is the form-work system from Architectural Concrete Creations that took home the “Most Innovative Product” award at World Of Concrete 2004. The integrated poured wall system makes it easier to attain vertical textured concrete surfaces while curbing the time and cost associated with traditional liner assemblies.

Arch-Crete’s standard 3-foot-by-6-foot panels consist of high-impact, wear-resistant composite materials. A dynamically designed grid matrix provides maximum strength during the pouring stages, limiting deflections.

The forms come in several natural stone textures: “Boulder Stone,” “Castle Cut Stone,” “Cobble Stone,” “Ledge Stone,” “River Rock” and a flat panel. This group of textures represents much of the below-grade geology in the United States, and more designs are in development.

Arch-Crete forms do not absorb water, are impervious to most chemicals, and also work with integral colors, release agents and other concrete additives.

For additional information, call (877) 753-6767 or visit www.arch-crete.com.

Western Forms

Western Forms encourages contractors to think brick with its Vertex Brick patterned form panels.

The pattern on these panels is touted as being the deepest in the industry, while well-hidden form seams and joints improve its look even more. Vertex forms are easy to strip, are available in a variety of form panels, including ones with PinLock Attached Hardware, and also last for thousands of pours. They turn out a poured concrete wall with a realistic, seamless brick appearance.

For more information, visit www.westernforms.com or call (800) 821-3870.

Metal Forms Corp.

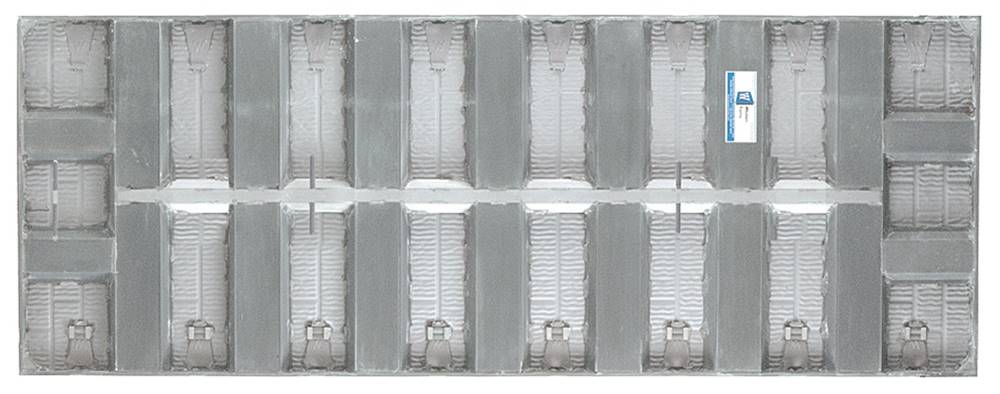

Metal Forms Corp., the makers of Poly Meta Forms, are fond of comparing their high-density polyethylene forms to wood, and if you were them, you would too. Poly Meta Forms are only half as heavy as comparable-sized wood pieces. They are reusable, they offer uniform straightness and height, and their size is guaranteed. This is unlike wood forms, whose uniformity is dependent on what happens to be at the lumberyard.

Poly Meta Forms set and strip quicker than wood does, with a wedge that unlocks and loosens the pieces after the pour has set. The wedge makes horizontal and vertical adjustments easier, too. The plastic forms also perform better than wood when it comes to absorbing moisture. They actually don’t absorb any moisture at all.

Poly Meta Forms come in both straight and radius forming designs and several different dimensions for variety. Top spacers, division plates and overhead hangers help when pouring curbs and gutters. You can bend these forms to suit when pouring curved slabs.

For more information, visit www.metalforms.com or call (414) 964-4550.

Symons

Form liner textures from Symons enhance the appearance of concrete walls and columns. Hundreds of standard patterns, in four different materials, are available for specification to create appropriate and attractive architectural finishes.

The liners come in four grades with varying life spans. SPS Plastic is a polystyrene form liner that provides an inexpensive alternative for single-use applications. ABS Plastic is an ABS form liner that offers durability and performance for projects requiring five to 10 uses. Dura-Tex is a urethane material that can be stripped from complex designs without damage. It is a medium-use liner good for roughly 40 uses. Elasto-Tex is a pure urethane form liner that provides consistent pattern reproduction. This liner offers an exceptional cost advantage when used 100 times or more.

All four liner types come in wood patterns, rib patterns, fractured patterns, custom designs and more.

For more information, visit www.symons.com or call (847) 298-3200.

Stegmeier Corp.

Stegmeier Corp.’s countertop forms are one-time-use foam forms available in five profiles. These arwe “Regular,” “Marble Round,” “Capstone,” “Diamond Cut,” and, new this year, “OG.”

Two profiles of backsplash forms are also available.

The line of concrete countertop forms is for cast-in-place installations of residential as well as commercial countertops. You may miter forms to fit corners or bend them to a radius as tight as 2 inches.

For more information, visit www.stegmeier.com or call (800) 382-5430.