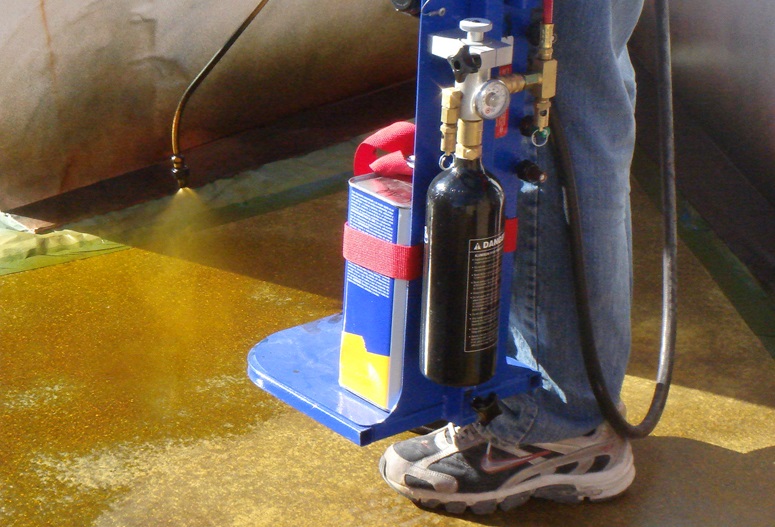

Photo courtesy of Versatile

Ever wonder where 21 square feet per bag or 300 square feet per gallon comes from? Coverage or application spread rates aren’t just a made-up number or educated guess. Determining coverage rates is always based on a mathematical constant known as the Theoretical Coverage Rate of a Coating. This in conjunction with surface conditions is how the rates are calculated.

According to www.powerwraplp.com, “The theoretical spreading rate or coverage of a coating is a function of the volume solids. The volume solids is the percentage of the coating consisting of binder and pigments which remain on the substrate, forming the final film after the volatile components or solvents evaporate.”

A less technical explanation translates into how much of the actual solids of the applied product will remain and how far it will go once the volatile liquid portion evaporates. The mathematical part is based on the constant that 1 gallon of any 100% solids material will cover 1,604 square feet when applied at a dry thickness of 1 mil (1/1000th inch).

Using this constant and the solids percentage of the product allows us to calculate the coverage rate of any material when applied to a smooth nonporous surface.

Example:

One U.S. gallon of sealer with 25% solids by volume will cover 267 square feet at a dry film thickness of 1.5 mil.

1,604 sq. ft. / 1.5 mil thick X 0.25 solids = 267 square feet

Most manufacturers will provide coverage ranges to take into consideration variations in surface smoothness and porosity. The smoother a surface the greater the coverage rate will be. The more porous a surface the lower the coverage rate will be. Understanding how coverage rates are established lets us better understand common decorative materials’ rate of application.

Stains and dyes

Most stains and dyes are based on a liquid carrier such as water, acetone or alcohol. The solids are usually reactive salts, pigments or dyes and don’t form a film. These materials don’t fall under the theoretical coverage rate equation since no coating or film is being formed.

The coverage rate for stains and dyes is based on how much material is required to develop the desired depth of color. In the case of a reactive acid stain, the industry standard coverage rate is around 300 square feet per gallon. This is based on testing that shows this rate provides the best color with the least amount of waste when applied to concrete.

In comparison, concrete dyes go much further, with an industry standard coverage rate of 500 to 700 square feet per gallon. This is based on the small particle size of the dye molecule, which ounce for ounce provides higher color saturation when compared to a stain.

Don’t confuse stains and dyes with tinted sealers or coatings that are sometimes called “concrete stains.” Tinted sealers or coatings will yield coverage rates based on the percentage of solids and applied thickness.

Cement-based overlays

Decorative overlays are treated like a 100% solids coating when it comes to coverage rate. In the case of microtoppings, the application is thin, with most ranging from 1/16 inch to 1/8 inch.

Coverage ranges from 200 to 400 square feet per 50-pound bag. The variation in coverage comes from the final thickness. It is usually determined by the top size aggregate (sand) in the mix.

When working with thicker overlays, like a stampable mix or patching material, thickness increases to a range of 1/4 to 3/8 inch. Because of this, it reduces the coverage rates. Standard coverage rates for 50 pounds of a thick section overlay:

1/4 inch 20 – 22 square feet

3/8 inch 16 – 18 square feet

1/2 inch 10 – 11 square feet

Coatings and sealers

Applied coverage rates of sealers can range from 75 square feet on the low end to 400+ on the high end. The big variation is once again based on percentage of solids and coating thickness.

Single-component acrylic sealers usually top out at 30% solids. These are applied between 1 to 3 mils thick. Therefore, after working the math, you end up with 481 to 160 square feet depending on thickness.

Looking at a high-performance coating, like a 100% solids epoxy applied 5 mils thick, the theoretical coverage rate is 320 square feet. This is right between the 250 and 350 square feet most manufacturers state in their tech data sheets.

The big variable in all these applications is the surface profile and porosity. As stated earlier, the theoretical values are based on a smooth surface. Any roughness of the surface negatively impacts coverage rate.

Dry broadcast materials

When it comes to broadcast materials like color hardener, release powder, flake and quartz, parameters specific to each product determine coverage.

Color hardener coverage rate is based on the amount of product needed to obtain a uniform color. Compared to dark colors, light colors usually require additional material to cover concrete’s base gray color. The industry standard is .7 to 1 pound of color hardener per square foot. It may also require additional material for special applications like exposed aggregate or polish.

Photo from Concrete Decor archives

Release powder goes a long way. Since the product must provide a bond breaker between the stamp tool and concrete, a fine dust layer is the only requirement. In most cases, 0.03 to 0.04 pound per square feet is the typical coverage rate.

Flake and quartz are usually manufacturer-specific when it comes to coverage rate. The size of the flake or quartz granule along with the desired level of saturation are the main contributors in application rate.

By the way

It is important to note that we base the strategies for determining coverage rates in this article on industry averages and application experience. It’s always important to read and follow the manufacturer’s application guidelines and recommendations when determining coverage rates.