You might call it a flight of fancy, this floor artistry in the offices of Fremont, California, pediatric dentist Dr. David Morris.

The artwork depicts kites, after all. No doubt youthful patients warm to the imagery and the idea behind its creation — a diversion in an otherwise angst-generating setting (the dentist’s office) that also serves as a fun, innovative way to guide patients and parents to the proper doors.

You’re there for regular exam? Follow the yellow kite streamer (or tail).

The doctor ordered an X-ray? Follow the red ribbon.

A bigger fix is in order, like fillings? Purple is the path for you.

The concept behind the artistry at Dr. Morris’s Young Smiles dental offices flows from the creative imagination of San Jose, California, designer Stan Royer, who calls himself a design strategist. But the credit for translating Royer’s “wayfinding” design into actual decorative flooring goes to Diamond D Concrete in Capitola, California, and its owner, Dave Pettigrew.

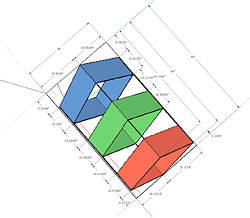

Diamond D Concrete employed its own custom-formulated microtopping system and custom-tinted color formulations — and a good measure of artistic skill — to turn Royer’s idea into a multicolored flooring installation built around a theme of airborne, three-dimensional kites.

The dominant artistic element is a large, multicolored delta-style kite on the floor of the front lobby with a wingspan of some 9 feet. In the kite’s wake flow five different-colored tails or streamers, each leading to rooms for different dental procedures.

Near the exit the young clients encounter another multicolored kite — a box-type design with a green tail swirling in the breeze.

“It’s the best way to provide a distraction,” Royer says of the floor-level design. “They look at the floor and find their way through the maze of offices while being entertained.

“It’s a distraction in a positive way, in that it helps the kids be more comfortable in a dental-office environment. It kind of evolved from the concept of a kite being something playful.”

Turning idea into art

Turning idea into art

Diamond D Concrete stepped into the picture after another contractor opted out of the project, says Pettigrew.

Pettigrew received an artistic retainer when work began, knowing it would take some doing just to successfully collaborate with Royer and Dr. Morris and effectively execute the kind of multicolored, elaborate imagery they had in mind. Planning got underway in consultations with Royer, Pettigrew recalls. “Stan’s a neat guy, a real thinker,” he says of the designer.

“Stan had a color palette he wanted to use. I took it and made samples of different colors,” Pettigrew says. To get the needed matches in matching custom colors, he purchases colorants at retail and then tinkers with additional tints, adjusting the shades to hit the target. In all, he formulated nine different colors for this project: Eucalyptus, Bamboo, Parrot, Hot Sauce, Baltic, Bayou, Apricot, Silver Pearl and Black Fudge.

Diamond D’s rough canvas for this work of art was an existing concrete floor in an expansive office space of nearly 5,000 square feet that was remodeled to serve as the new home of the dental practice. The concrete had been stripped of previous flooring, but it needed thorough cleaning and surface preparation, including a grind using a heavy-grit diamond to facilitate adhesion of the flooring system. Following a sweep and thorough vacuum, any cracks in the existing concrete were repaired using Crown Polymers’ CrownFlex 500 epoxy-based concrete-repair material.

The surface was ready for a flooring application, except for one important detail: moisture measurement. Pettigrew calls this a crucial component of any concrete-floor treatment, dictating whether a vapor barrier is needed to prevent subsequent flooring failure.

“I’d say 98 percent of failures with a microtopping are due to vapor lifting up through the slab,” he says. If a moisture meter indicates a vapor emission rate of greater than 3.5 pounds per 1,000 square feet or more, application of a vapor barrier is required, Pettigrew says.

In this case, meter readings ranged from 4.5 to 5.25 percent. “My policy is that I won’t warranty a floor with more than 3.5 pounds (emission rate) without putting vapor barrier down,” he says.

Diamond D Concrete applied Crown Polymers’ CrownCote Vapor Barrier, a liquid, 100-percent solids epoxy. After an overnight cure, the crew applied a base coat using Crown Polymers’ CrownShield 50, a high-build, 100-percent solids, two-component epoxy coating. This was followed immediately with a sand broadcast “until rejection,” Pettigrew says, meaning complete coverage. After an overnight dry, any loose sand is swept up, leaving what he calls a “sandpaper floor” that ensures a strong mechanical bond of the microtopping. The approach is standard practice for Diamond D in these applications.

Diamond D Concrete applied Crown Polymers’ CrownCote Vapor Barrier, a liquid, 100-percent solids epoxy. After an overnight cure, the crew applied a base coat using Crown Polymers’ CrownShield 50, a high-build, 100-percent solids, two-component epoxy coating. This was followed immediately with a sand broadcast “until rejection,” Pettigrew says, meaning complete coverage. After an overnight dry, any loose sand is swept up, leaving what he calls a “sandpaper floor” that ensures a strong mechanical bond of the microtopping. The approach is standard practice for Diamond D in these applications.

“We’ve never had a failure with this floor,” Pettigrew says.

Then comes the main act — installation of the microtopping floor. The flooring material is something of a closely guarded secret — a trowel-applied material formulated by Diamond D using portland cement, a polymer and pigment colorants purchased separately and blended on-site.

Microtopping installation begins with an initial base coat, then the primary-color coat the next day — in this case a green shade, Eucalyptus, specified in the design by Royer. Once it had dried, Pettigrew and Diamond D superintendent Cesar Carillo sprang into action, marking the design on the floor and applying painter’s tape that functioned as a stencil for application of the various custom colors of microtopping.

Application requires considerable skill with trowels, mastered by Carillo over more than 20 years with Diamond D.

Application requires considerable skill with trowels, mastered by Carillo over more than 20 years with Diamond D.

“He’s a right-hand man. I don’t know how we would do this stuff without him,” Pettigrew says.

A visual experience

Pettigrew gives high marks to designer Royer for conceiving an innovative idea and effectively working with Diamond D to make it work.

“The idea was to give them (the young patients) a visual experience, which he’s really done,” Pettigrew says of Royer.

“The difficult part of this was getting the colors right. He (Royer) had a color palette, and I had to make them. And keeping those consistent over a large area … making designs that flow down the hallway. That’s not an easy thing. We hadn’t done this many colors in a project before. There’s so much movement in the floor, and he wanted those kites to float above that green floor and give a 3-D feel, and that takes some work.”

The three-dimensional effect required nuances in shading to produce shadowing that would exist in a natural setting, Pettigrew says.

The three-dimensional effect required nuances in shading to produce shadowing that would exist in a natural setting, Pettigrew says.

Dr. Morris says the end result delivers what he had hoped to achieve based on conversations with designer Royer.

“It took a few tries to get the kites the way I wanted, but I think they do give the 3-D effect we were looking for,” Dr. Morris says. And the result serves the functional purpose intended, too. It’s a wayfinding feature that also provides a diversion for the youthful clientele.

Jackie Levinson, a longtime friend whose children are Dr. Morris clients, gives the finished project a ringing endorsement from an important client segment — Mom.

“It’s a beautiful floor, it’s playful,” Levinson says. “It’s functional, easy to clean, and vibrant.”

Levinson, also a client of Royer’s, introduced him to Dr. Morris. “Stan designed our kitchen and he’s an amazing designer,” she says, adding that she was in the loop on the Young Smiles project as it developed.

“It’s really a showstopper, the true showcase of the office,” she says. “It pulls everything together — the paint, tile, and finishes.”

Royer says he frantically searched for a decorative concrete contractor that could take on the job after the initial contractor bowed out. From online searching, he concluded that only three companies in Northern California could pull it off.

“Diamond D was able to step right in and make it happen. They were a lifesaver. We were thinking we’d have to go back to the drawing board.”

“Diamond D was able to step right in and make it happen. They were a lifesaver. We were thinking we’d have to go back to the drawing board.”

“We made some adjustments on-site, tweaked some things, but it worked. We wanted a three-dimensional feeling, to where you are hesitant to jump on the kite. Maybe we didn’t quite get that, but it does cause a distraction and gets your attention.”

If the 3-D effect came up a bit short, it may be due to the limitations of the solid-color microtopping material, Royer guesses. “To get that effect you’d have to have a greater range of shadings,” he says.

Project at a Glance

Client: David Morris, D.D.S., Young Smiles, Fremont, California.

Decorative concrete contractor: Diamond D Co., Capitola, California | www.diamonddcompany.com

Color formulation and application: Dave Pettigrew and Cesar Carillo, Diamond D Concrete

Architect/designer: Stan Royer, Royer Designs, San Jose, California

Project manager: Eric Hemminger, Hemminger Construction, Grass Valley, California

www.hemmingerconstruction.com

General contractor: Paul Aboumrad General Contractor, Fremont, California

Scope of project: Installation of decorative multicolored microtopping floor system in pediatric dentistry office, with design featuring kites and streamers (tails) functioning as “wayfinding” devices

Most challenging aspect: Custom formulation of nine microtopping colors to match specified colors; successful execution of complex, multicolored designs with trowel application of microtopping; achieving three-dimensional effect on decorative elements

Products used: Custom microtopping mixture of polymer, cement and pigment color; Crown Polymers’ CrownFlex 500 epoxy repair material, CrownCote Vapor Barrier (Product No. 303) 100-percent solids epoxy, CrownShield 50 (Product No. 320) high-build, 100-percent solids two-component epoxy coating; sand