First Place, Residential

Hollow Rock Designs Inc.

Bar top in a condominium, St. Paul, Minn.

From the Contest Entry:

The condo is very upscale contemporary. The client wanted a very rough counter wall/top combination with a polished top. The back of the concrete wall was used to incorporate a stainless steel trough sink. The top was grey.

The bar top is used for entertainment on one side and cleanup on the other side.

The piece was given to us with a suggested size and it was left to us to create the aesthetic. The combination of a formed bridge abutment with the sleek top finish adds a campy flavor.

The piece weighed more than a ton and had to be formed and poured up against a wall. The piece was hoisted into a truck for delivery, and with the use of a crane, and an entire city block barricaded, it was raised five floors and ramped through the balcony deck doors. Then, it was jacked up with hydraulic jacks and wheeled carts to a point where it was flipped end over end across the living room to its resting place using huge solid foam bumpers to absorb the tumbles.

From the Judges:

Fantastic design. The top looks gorgeous; nice contrast between polished top and rough face. — Jeff Girard, Concrete Countertop Institute

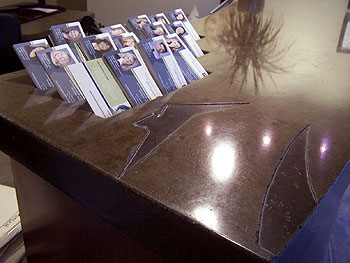

First Place, Commercial

First Place, Commercial

New Edge Design

Neighborhood Mortgage countertop, Bellingham, Wash.

From the Contest Entry:

This job was for a reception countertop at a mortgage brokerage firm. It has an inlay of their business logo along with integrated slots for their business cards, plus radius edging.

From the Judges:

Very nice piece. Simple but elegant. The placement of the logo ties nicely with the positioning of the business cards. Good job on the curves. They are clean and true.

— Jeff Girard, Concrete Countertop Institute

Runner Up, Residential

Runner Up, Residential

Absolute ConcreteWorks

(tie) Rotter residence kitchen, bathroom and patio awork, Olympia, Wash.

(Rotter) The BBQ surround was stained to complement and accent the colors in the stone surrounding it.

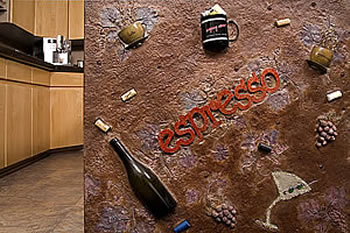

Hayvaz residence kitchen and espresso bar work, Shelton, Wash.

Hayvaz residence kitchen and espresso bar work, Shelton, Wash.

From the Contest Entry:

(Hayvaz) A multipurposed three-dimensional art piece also serves as a removable end wall panel, providing access to lighting controls for the adjacent glass block wall. Embedded keepsakes included espresso cups, a wine bottle and corks from the client’s winemaking business, and representations of vines and leaves from the vineyard.

Runner Up, Commercial

Runner Up, Commercial

Hard Topix Precast Concrete

Master Precision Global conference tabletop,

Greenville, Mich.

From the Contest Entry:

The work top is 40 inches by 96 inches by 2 inches thick weighing in at almost 600 pounds. The precast mold was built using melamine, and Master Precision’s custom logo was then set in the mold. A GFRC concrete mix was tinted with black integral color sprayed on in three heavy coats and then backed with black standard concrete mix reinforced with fiber mesh and No. 4 rebar. The concrete top was cured for four days before the pearl color shift was applied.

The work top is 40 inches by 96 inches by 2 inches thick weighing in at almost 600 pounds. The precast mold was built using melamine, and Master Precision’s custom logo was then set in the mold. A GFRC concrete mix was tinted with black integral color sprayed on in three heavy coats and then backed with black standard concrete mix reinforced with fiber mesh and No. 4 rebar. The concrete top was cured for four days before the pearl color shift was applied.