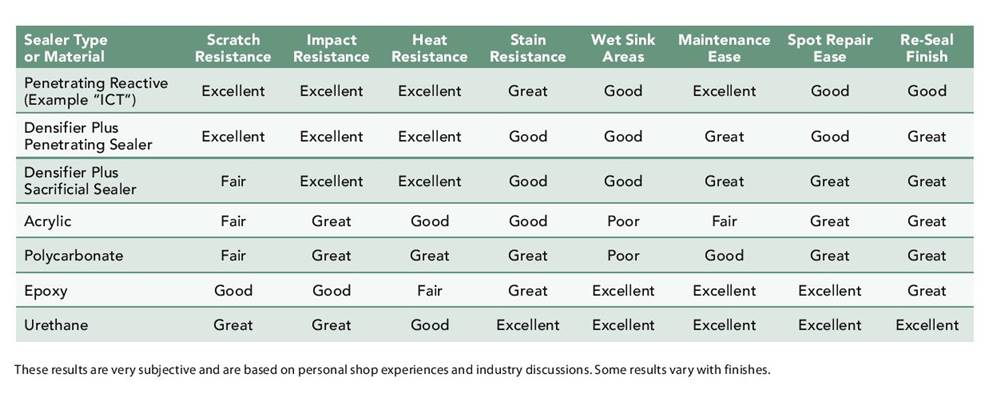

Everything chips, stains and scratches to some degree. Anyone who tells you otherwise is lying to you. It is the degree to which a given material will survive damage that concerns us. The same is true for concrete countertops. This is why predicting performance of concrete countertop sealers is so important.

Also, when something does chip, scratch or stain, ease of repair is of the upmost concern to our fabricating company, J&M Lifestyles.

Concrete has many faces, and there are many preconceived and misconceived ideas about it. You should not navigate what people think concrete is — instead, explain to them what it actually is. This includes your concrete, its finish and all of its attributes.

Setting expectations is the most important job we all have, so that people in general understand what it is to own a custom-fabricated product, not an assembled product. These expectations are based on your personal experience, not mine or anybody else’s. Your knowledge and experience with concrete, as a contractor or as a homeowner with concrete work, and your persistence in improving your skills are your most valuable assets.

When it comes to concrete countertop sealers, I cannot place into your head all my unique experiences of what sealers have worked or what it is like to strip a top and reseal and hope the client will accept it. But I can describe the sealers we have come to use over the years, and I can try to describe their role in what we do at J&M Lifestyles.

Generel observations

Let’s start with some general observations. If you use a silicate or penetrating sealer on a ground finish you can cut on, scratch or scrape on, the surface will end up having a visual aesthetic akin to that of engineered ground stone. It also may not be as stain-resistant, easy to fix or reliable as other finishes.

If you have a surface that has a delicate texture or that is acid-stained, you will want to use a finish that builds to protect it. You may not be able to cut or scrape on it, but it will be very stain-resistant in some cases and may even be easily repairable.

Interior jobs

Indoors, there are fewer variables and elements to consider. There is no rain, very little direct sun, and usually a controlled temperature. There is little expansion and contraction and no hydrostatic pressure.

To make interior tops, we use modified composite concrete from SureCrete Design Products. It is a reliable, consistent material, and like a polymer-modified GFRC, it is very dense and has a low vapor absorption rate that will not transfer moisture or wet through.

Your choice of a sealer depends on the finish you are applying to your concrete, whether it be cream, slightly ground, cast texture, hand-trowelled or stained.

Reactive sealers

Most reactive sealers are classified as “densifiers,” silicates that react with the concrete, creating a chemical change. These finishes will harden the concrete surface and make it tighter, but they may still allow etching and often will need a sealing component.

Reactive sealers create a harder crystalline structure suitable for a ground surface or cream finish. However, if the surface is then blemished or stained, there is no topcoat to contain a repair. If the surface is ground, you will not be able to bring back the cream finish.

(Blue Concrete recommends that its ICT reactive sealer be used alone, without another sealer. However, the sealer’s reaction process needs heat and is time-consuming — it may take a couple of days. It’s best for you to keep the piece in your shop to properly QC its reaction.)

Penetrating sealers such as silanes and fluoropolymers repel liquids and pair nicely with some reactive sealers. Penetrating sealers also offer heat resistance — however, they still may allow oils to penetrate the surface. Some penetrating and reactive sealers can also be used in conjunction with a topical sealer, a sacrificial surface that can easily be applied by the homeowner.

Types of topicals

Topical sealers are vast and prolific in the concrete field. The most common is an acrylic sealer, used in tandem with a sacrificial wax component. This is a single-part, easy-to-use and easy-to-repair sealer. However, it incurs a good amount of maintenance or repair due to its poor scratch resistance and limited stain resistance in countertop applications.

This isn’t all bad. The wear over time creates a patina effect that changes and varies the surface of the concrete, much like the patina on metal. If properly presented to the customers, this is a purist type of artisan finish, very often the choice of leading artisans like Tommy T. Cook.

Topicals typically offer UV resistance and can be used outside. However, be sure to test the product you are using for yourself.

Polycarbonates, which act like acrylics, offer the same ease of application and limited scratch resistance but also high heat resistance. One from Pro-Seal Products Inc. couples this with fair acid and stain resistance and excellent UV stability. It is nontoxic and can be given to clients to reapply as necessary.

Epoxies are two-part and also easy to apply. They have a good bond but tend to scratch easily — still, they offer much better scratch resistance than an acrylic or polycarbonate. They are not UV-stable. Epoxies tend to be easy to repair, although good finishes almost always require a “seam-to-seam” reseal of the whole piece. The stain resistance is fair to good.

Urethanes

Urethanes are superior with scratch resistance to any we’ve covered in the coating category thus far. These coatings were once hard to use, but that is not the case anymore. Water-based urethanes such as one offered by Richard James Specialty Coatings Corp. have been used for many years. They have had a great degree of success. These coatings can be used in conjunction with other systems as well. Urethanes offer great scratch resistance, UV stability and excellent stain resistance.

Until recently, repairs with urethanes that were not solvent-based were very difficult and time-consuming, especially in areas that needed to be waterproof. Surecrete’s XS-327 is a high-solids hybrid urethane that can be colored, thinned and applied with varying solids content to achieve different degrees of finish, but it is also waterproof in spot sealing. We favor water-based sealers like these for their environmental attributes and their application ease during a reseal in a home. Remember, when (not if) you have to repair a top someday, typically five to 10 years after installation, that if you did your job correctly, it still should be in relatively good shape. Note also that the multiple-step, multicomponent system and its time frame is limiting for production shops.

A topical sealer has advantages — the stain resistance is reliable and consistent and the application method and final outcome is easy to test or observe. Delamination is the greatest concern with topical sealers. Experience helps a lot, but you are at the mercy of the products that are being supplied to you.

Fear the unknown

Other coatings are available but J&M Lifestyles has had limited experience and use with them. Polyaspartics are very scratch-resistant and typically very stain-resistant. However, as with any sealer, be aware of the MSDS, as certain sealers classified as polyaspartic can be hazardous.

Also, in some cases polyaspartics may be difficult to work with — and not conducive to spot repairs — due to their fast set times and difficulty in finishing. Remember that you will get debris on a surface at any time and sanding and polishing a surface to an acceptable finish is necessary.

The newer technologies that blend different chemistries are not always categorized or marketed as what they actually are. Many companies for the sake of privacy and intellectual property protection will market a new technology as something other than what it is. Rely upon the experience of others, the reputation of the company producing it, and your experience and observations.

The following story outlines one of the other concerns that need to be looked at when choosing a sealer — a change in an existing product.

I had personal experience with a few variations of a nano-type sealer, a topical silane. After years of excellent performance and consistent success with it, we started having severe failure rates of 10 percent. This totalled more than $100,000 in damages with no recourse. This was coupled with poor and relatively nonexistent troubleshooting of its application, storage, QC or factory defects. It has been brought to my attention by numerous fabricators that we were not alone in seeing the failure of the product. What was once touted as an outdoor UV-stable, resealable, waterproof and reliable sealer turned out to fail on all accounts 10 to 20 percent of the time, beyond applicator error.

In conclusion

I implore you to seek out products from companies with long track records in concrete. Look for companies that offer reliable consistent service, that offer products and materials in a system. Also, look for companies that manufacture their own sealers.

Use whatever products you choose consistently and record all of the information available when you seal a piece. We use a finish order to list the sealer, secondary and tertiary color applications. We also use this to take note of the weather, the steps taken and time frames. Additionally, we note the date after cast, moisture content and whatever other info is available. This sheet gets filled out when we are mixing and inducting sealers or cleaning up.

It is also good to think about the self-maintenance schedule. There is one available from Cheng Concrete that includes wax application by the clients. This is a great responsibility to give to a client. We use a sacrificial liquid wax that wipes on. It dries in minutes to create a hard film that is clear, UV-stable. Additionally, it gets rid of the superficial scratches in the surface.

A sealer such as the Pro-Seal polycarbonate allows a patina over time that is alluring. This is especially true in a commercial setting that gets a lot of use. Pay employees to maintain the area and they can easily apply a wear coating for durablity.