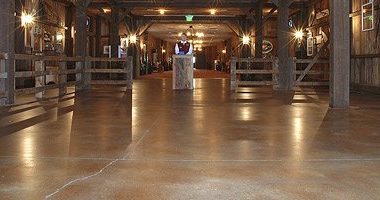

The 34,000-square-foot colored and stamped concrete courtyard that Allied Concrete Applicators poured at Saint Martin’s University in Lacey, Wash., presented a laundry list of challenges that had to be dealt with during installation.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognizing you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.